Coolest Tool In the Shop: Rumag REVG-s!

There are those moments. Opportunities to take stewardship of classic pieces, to learn, to preserve and maintain. Today was one such day.

To the best of our ability we brought in a 1953 Rumag REVG-s vertical milling machine that, at least, will become the ultimate drill-press in the shop.

It came from the collection of a great customer and machinist who had purchased it out of Ontario. He says that the 4-speed motor and 3360 rpm likely indicated that this was special-order machine to do fine drilling.

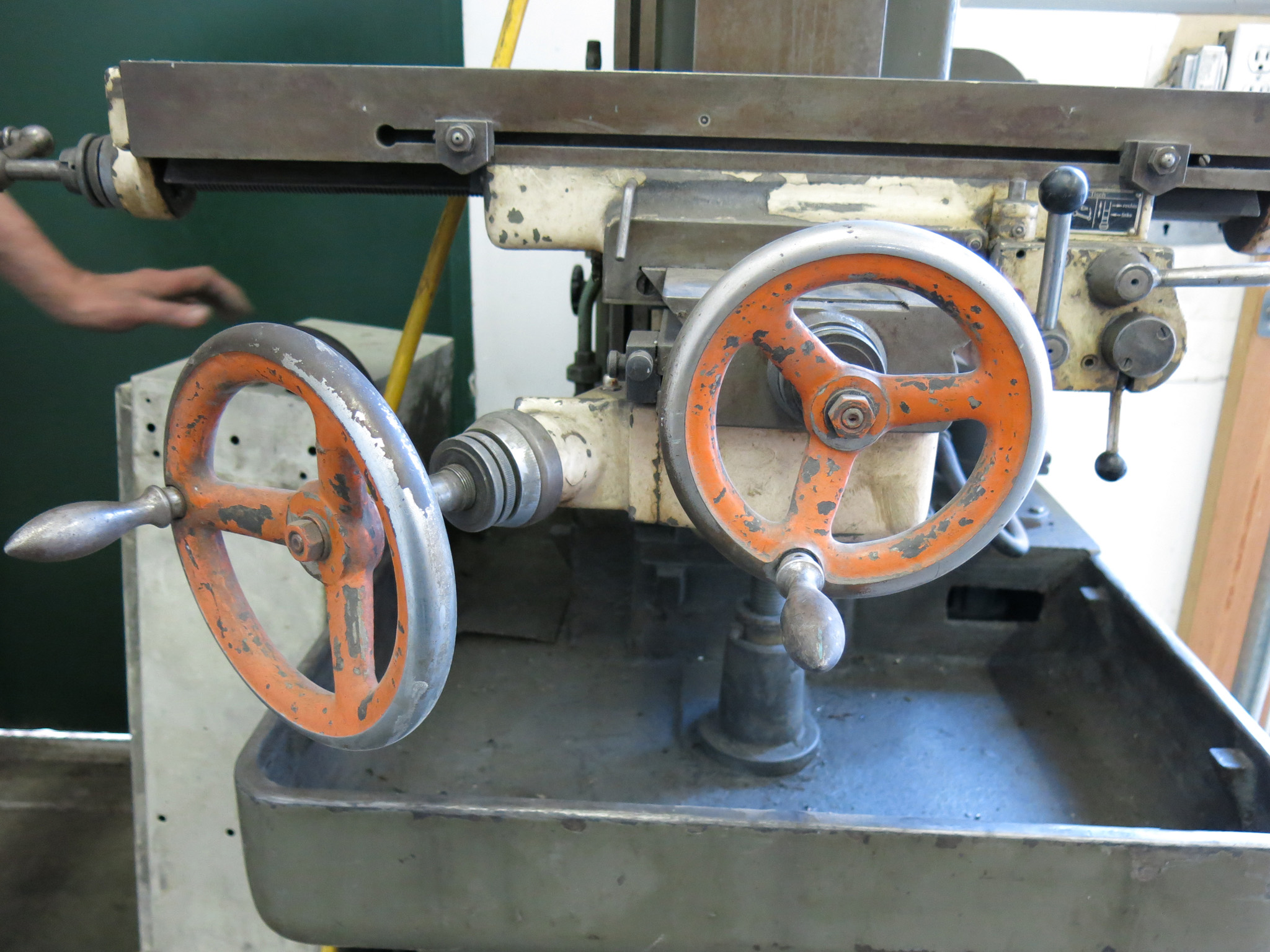

There’s lots to admire, the German precision, the original fit and finishes, the off-white table, the orange controls.

Hopefully through this post we can find someone that might have a manual, probably in German, although the intuitiveness of this design makes it fairly straight forward.

You’ve got a great machine in good condition, looks like an original paint job. It is in better shape than mine (which made it less than 50km from the manufacturer location since 195x …). As far as I can tell from the pictures, only the cover plate for the cutting fluid basin is missing, the window on the side cover is dull and Z axis stop is not original. Thanks for the reference pics! They will help me to bring my “new” milling machine closer to its original state.

Any luck on the manual? There is a discussion on the machine from Nov’14 onward over here with lots of pics ( http://forum.zerspanungsbude.net/viewtopic.php?f=60&t=13530 ). As far as I can tell from the discussion, no-one over there got a manual.

What a great machine! Very clean.

We finally found the serial plate for our RUMAG behind the access door. I will try to remember to post that up.

Thanks for the comments, it’s hard to know where to start with these machines.

Couple of tips. That spindle and motor will operate up to a one inch milling cutter or drill. Should you do that?? Yes if you use a good vise and the table screws backlash is within factory limits for safe operation along with the table locking devices.

For small diameter precision drilling do not feed the spindle into the work piece. Fix the workpiece in a suitable vise or other fixturing into the spindle, bring spindle down to half it’s stroke and feed the workpiece up on the table screw in minimal amounts, removing the drill from the workpiece to clear chips, then back down to the spindle stop and feed the workpiece in increments. This will work with a carbide milling or drilling cutter without breaking it. Always use the table screws in a clockwise direction. Set location and use the dials for a table move. Love older machinetools