Had the nice opportunity to join some friends and visit an old shop, tucked away far in the BC forest called A&A Chassis.

Out in the wilderness of Highlands, BC, A&A is an impressively stocked shop dedicated to metal fabrication and chassis construction like the type you would find in a sprint car or motorbike.

Keith showed us one seriously badass 1964 El Camino known as Roadstourmino which only a silhouette of its 1964 beginnings.

The reason we visited A&A was to pickup Jan Hoel’s incredible Esprit S3R which is a completely re-envisioned Lotus Esprit. A&A chassis welded up an entirely new frame which has an all-new suspension, but retains a Lotus Turbo engine. I can’t even begin to recall all the mods made on this incredible project, so if you’re interested, here it is on facebook: https://www.facebook.com/pages/F1-Motorsports-Lotus-Esprit-S3R/

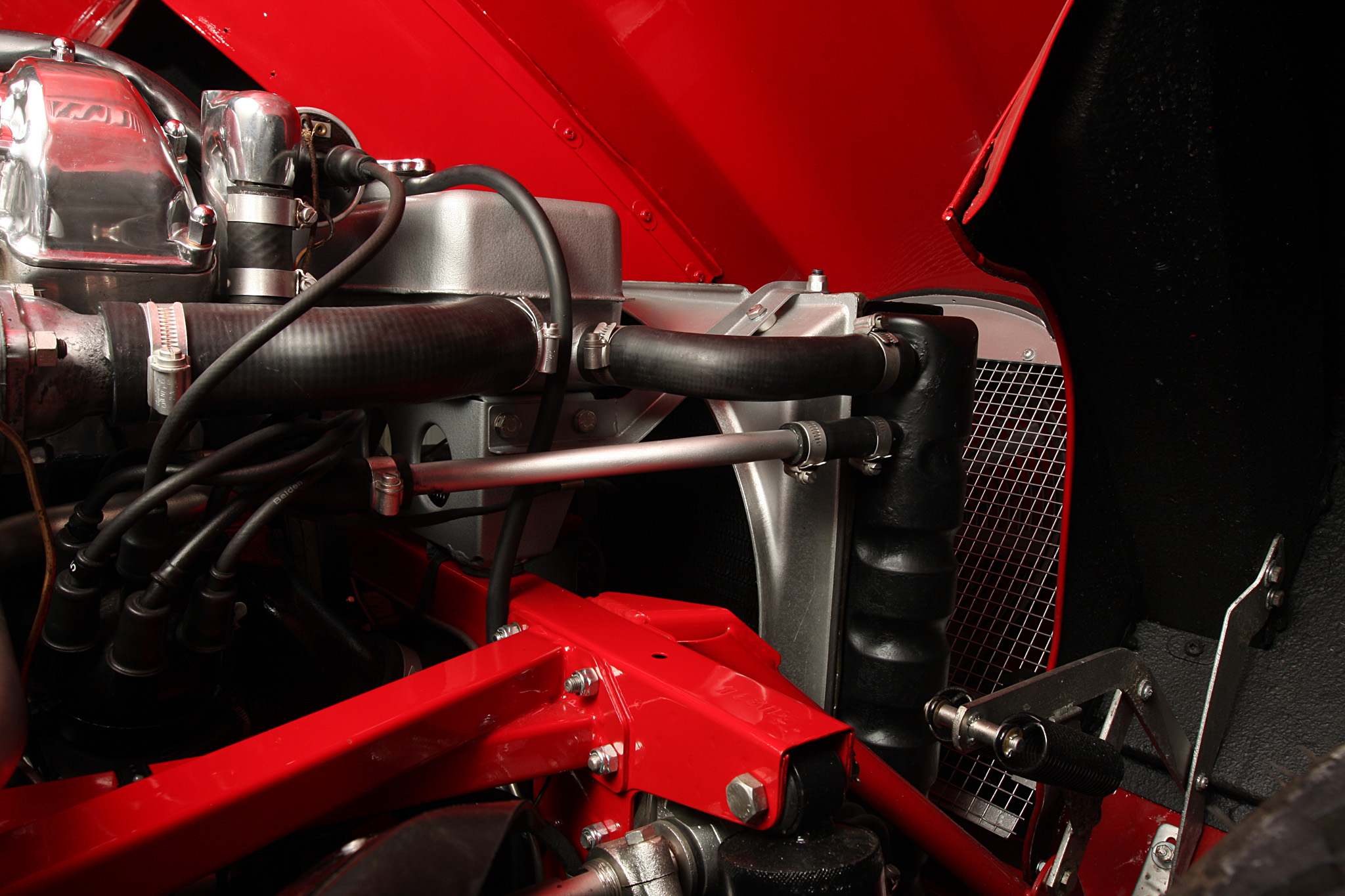

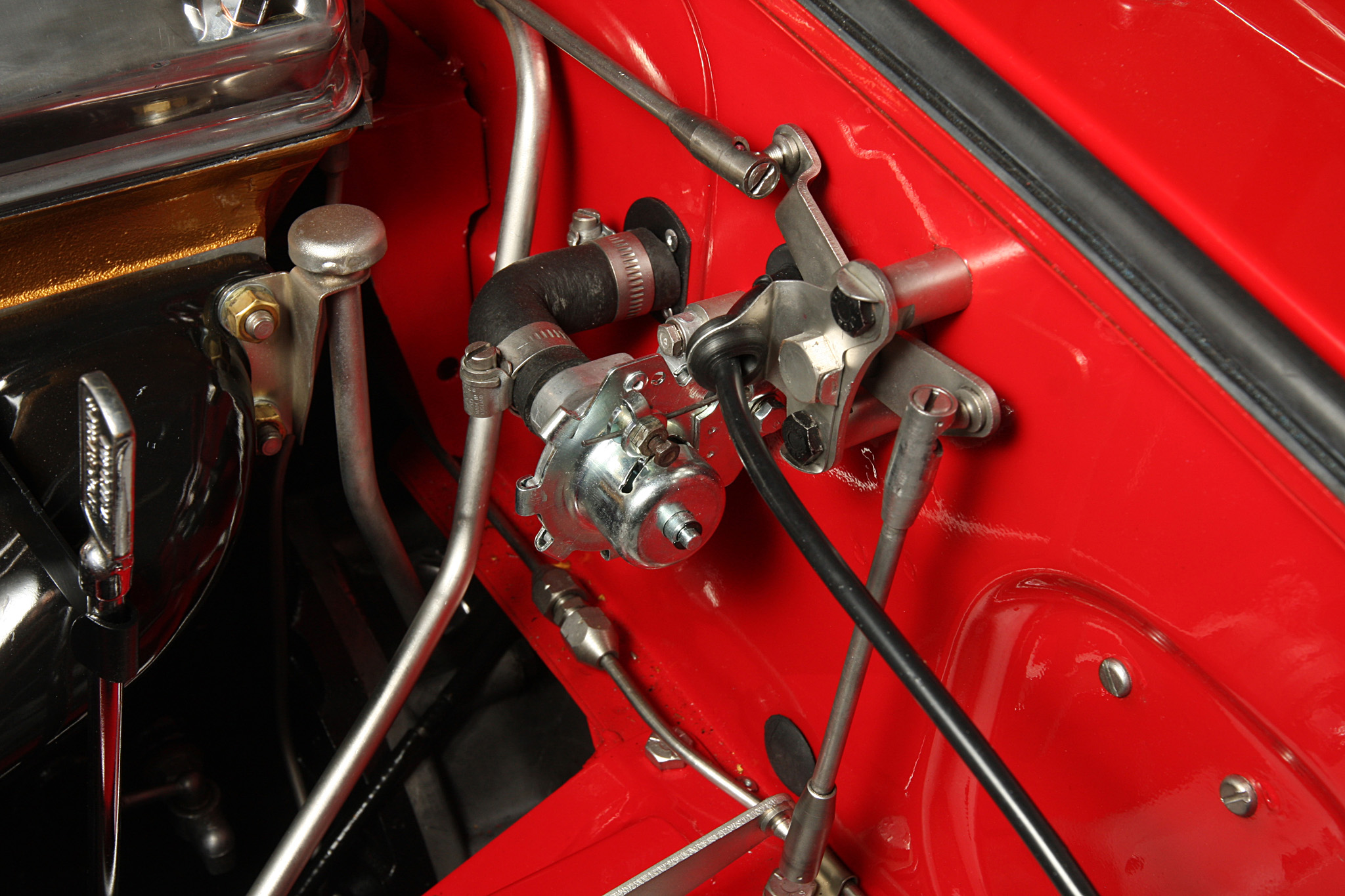

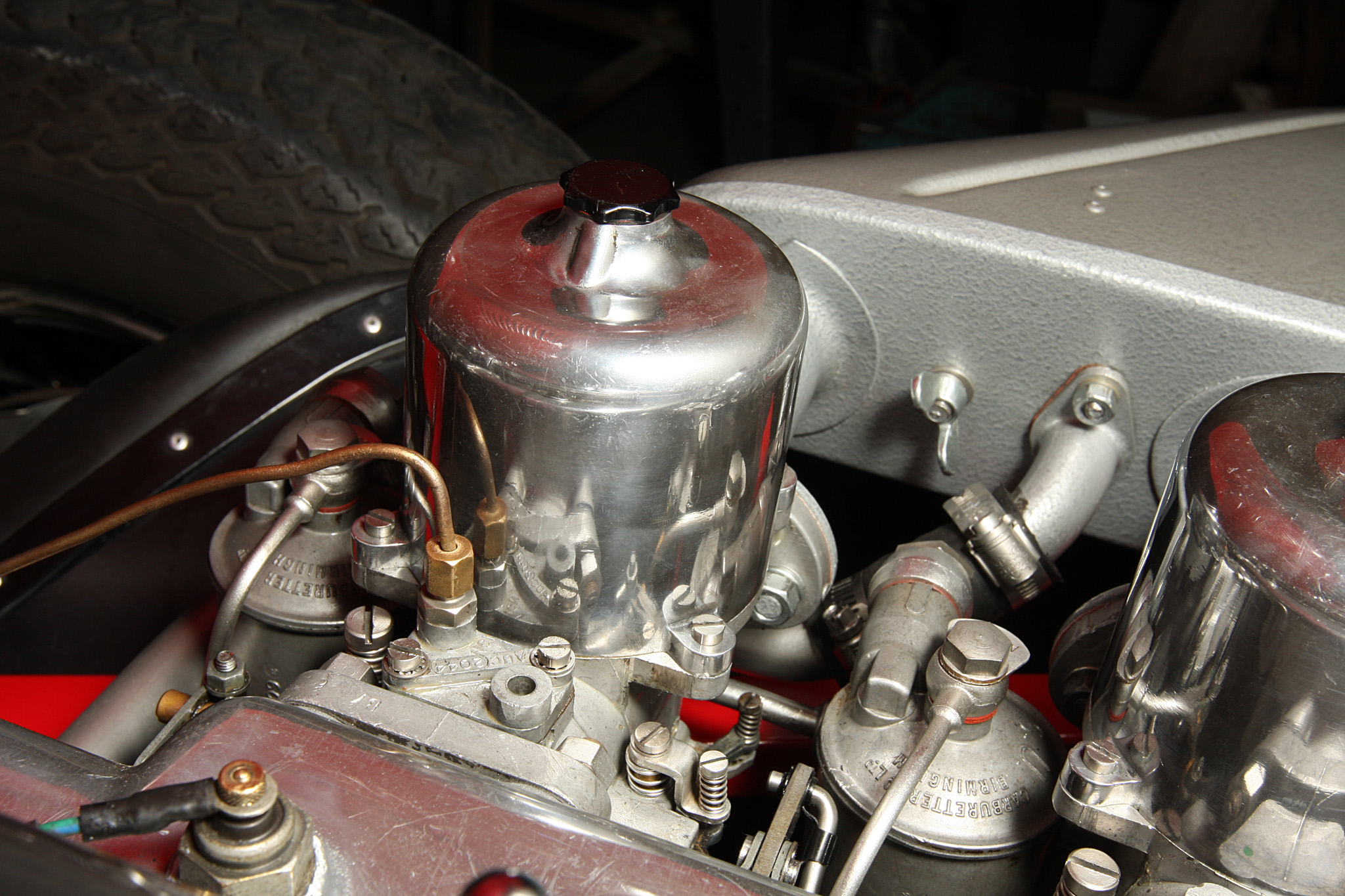

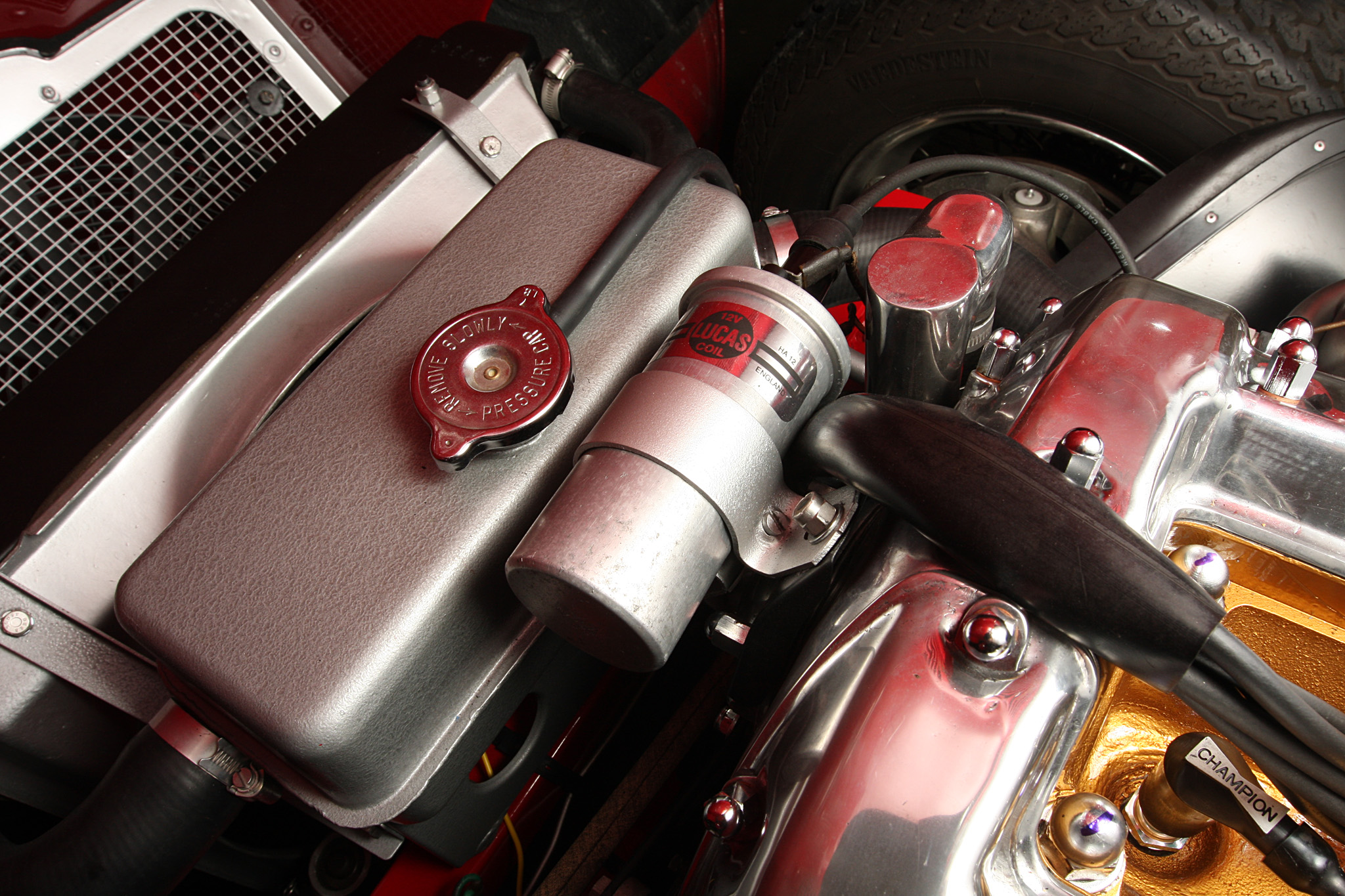

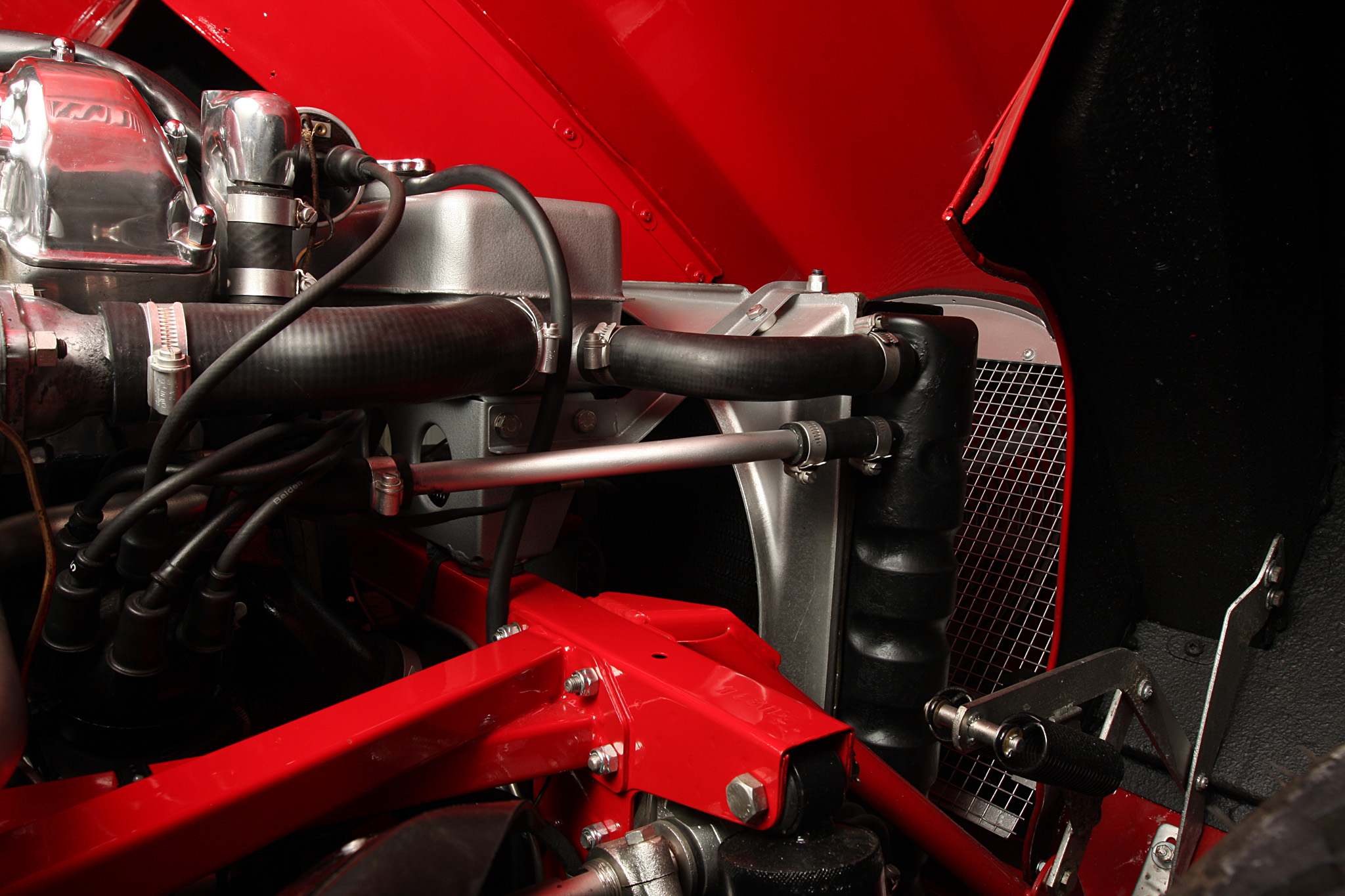

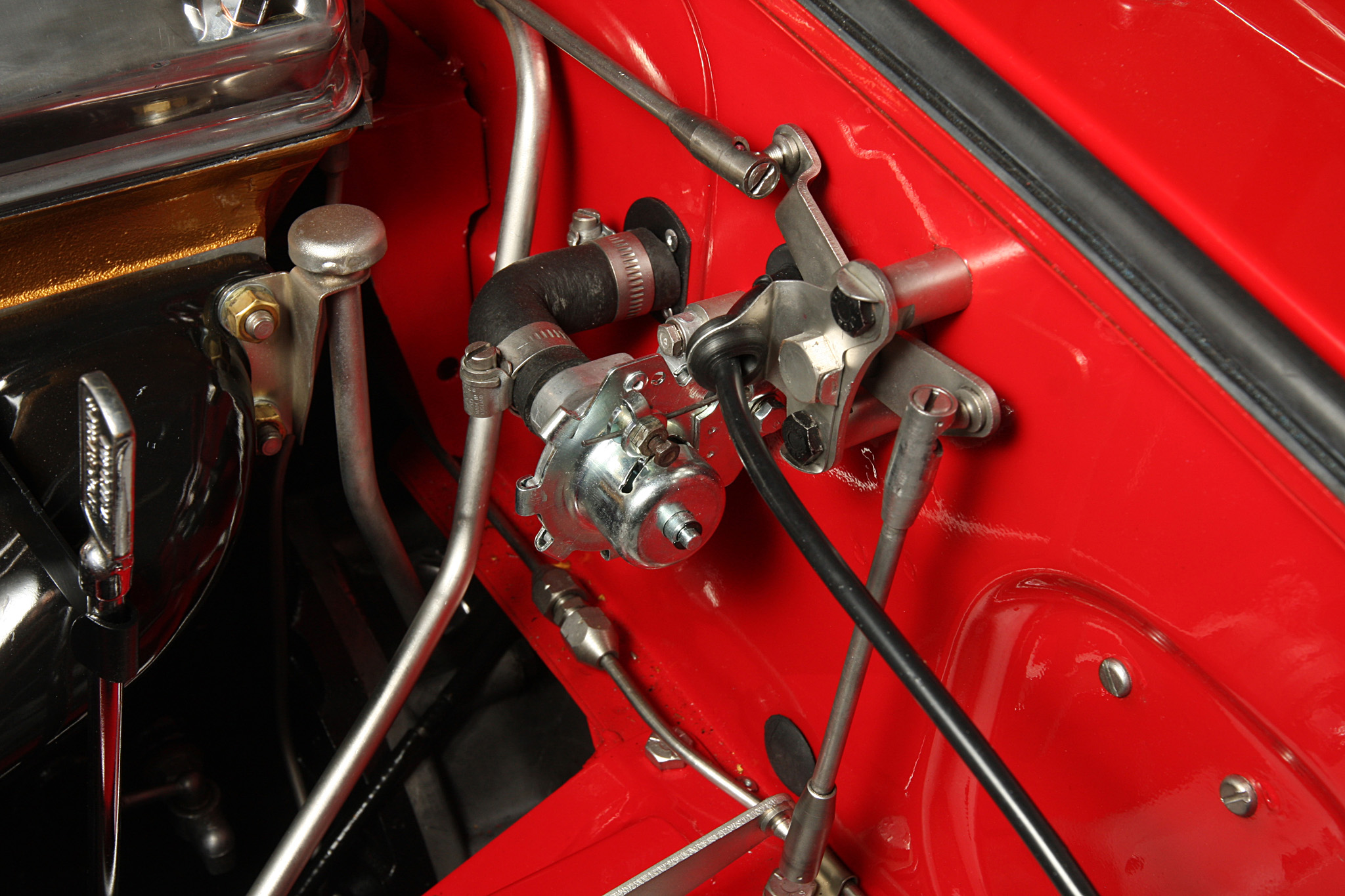

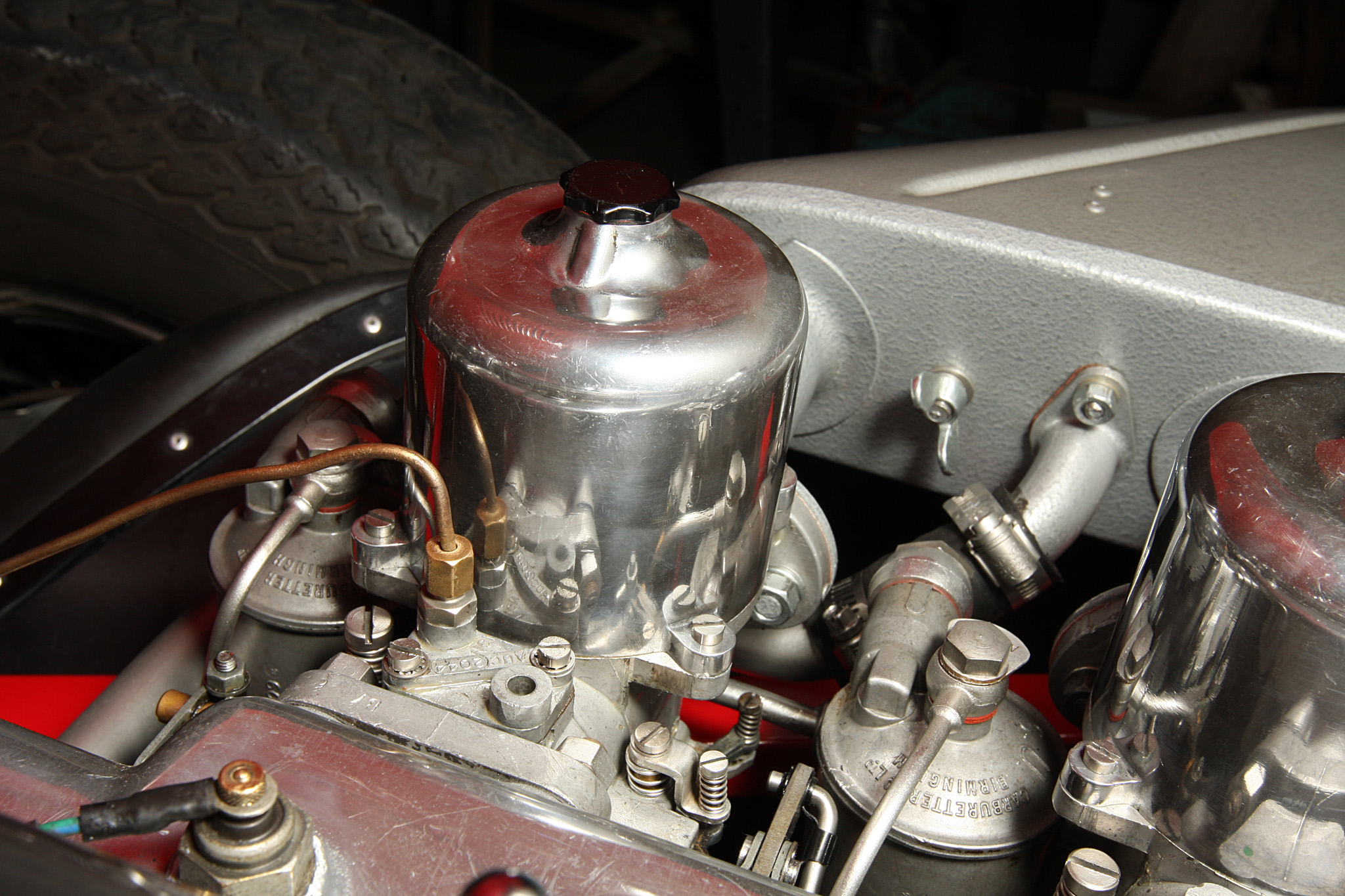

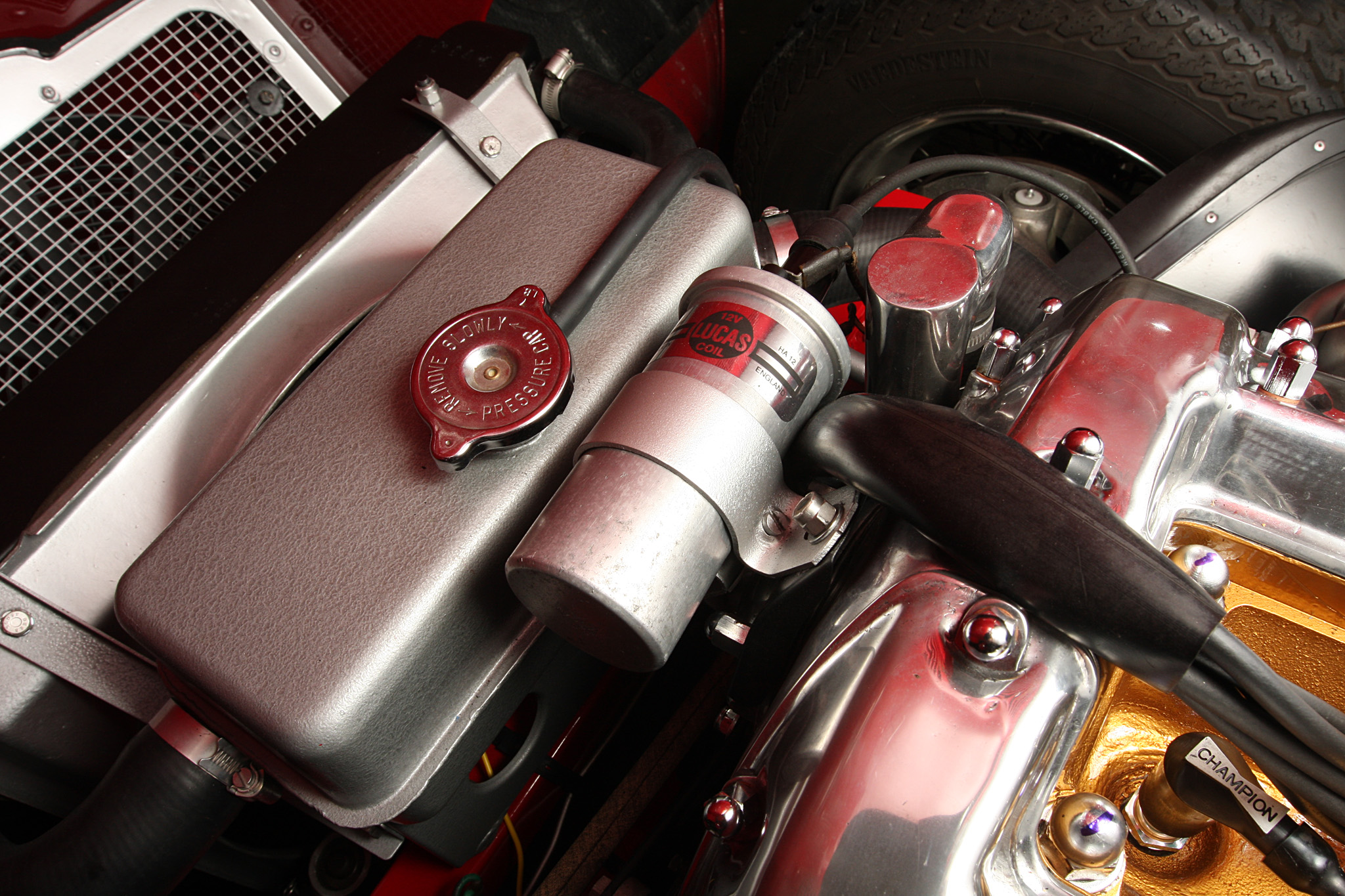

Never got around to posting up some completed images of our MG TF restoration project, so here it is.

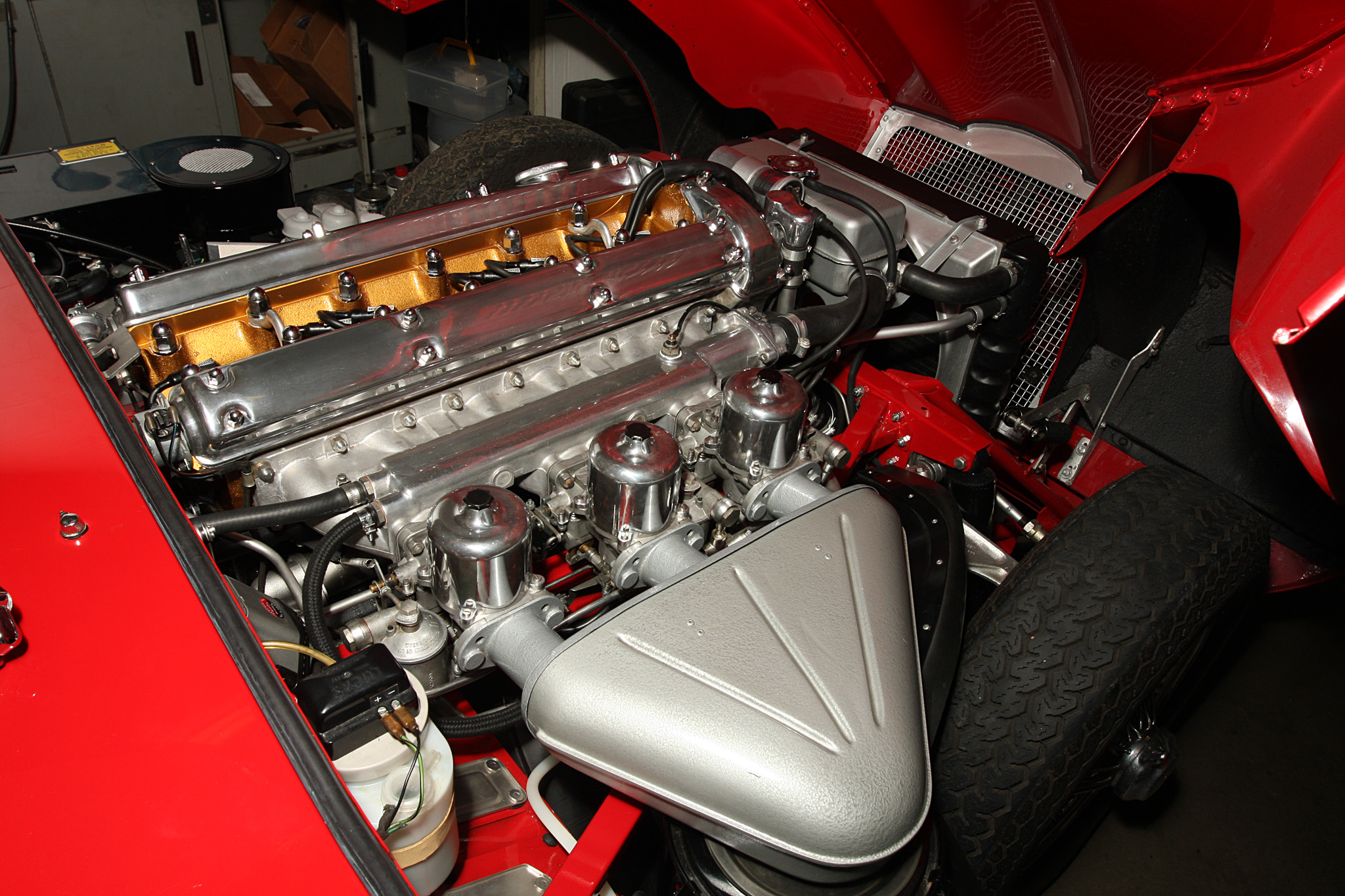

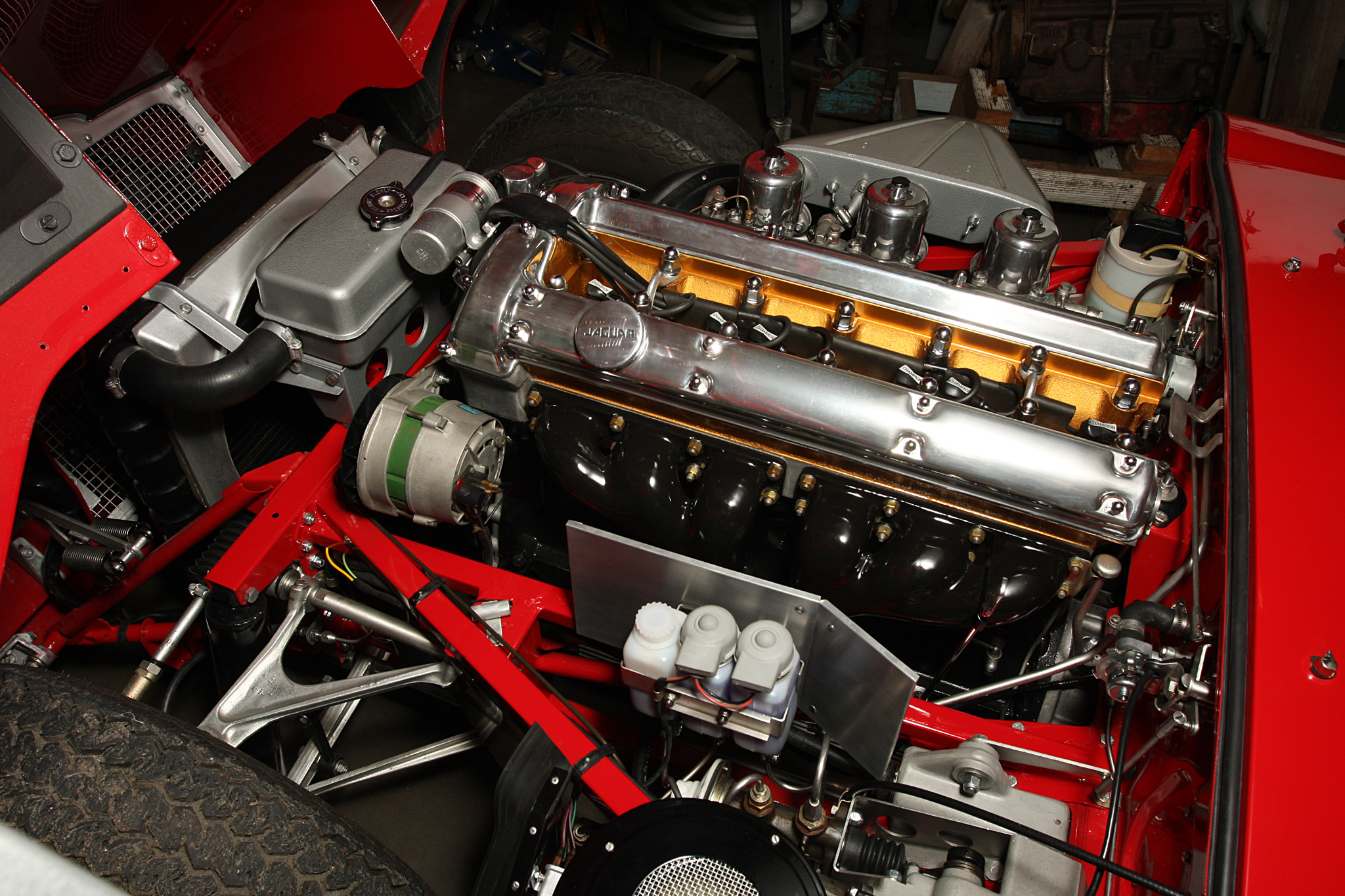

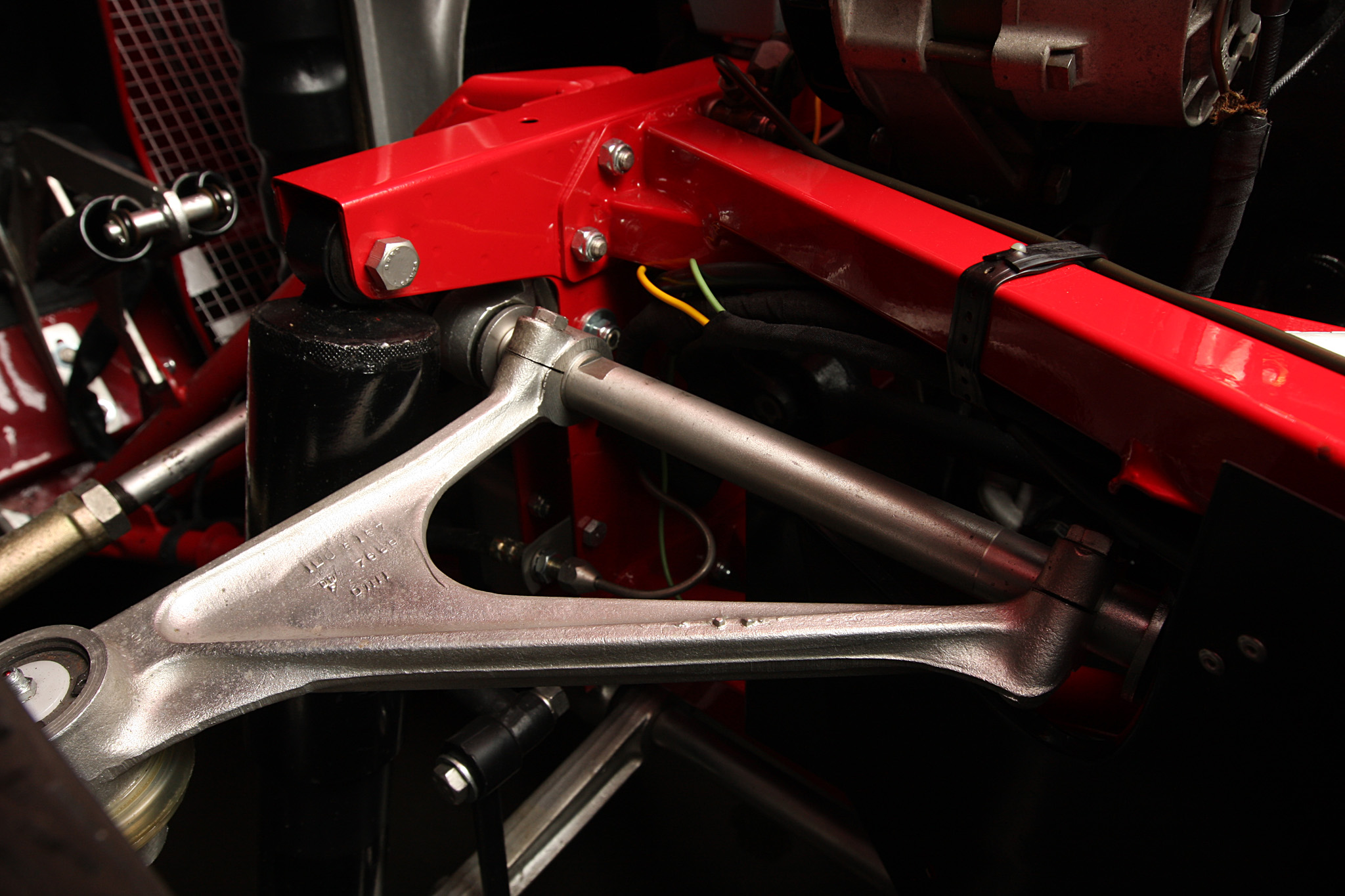

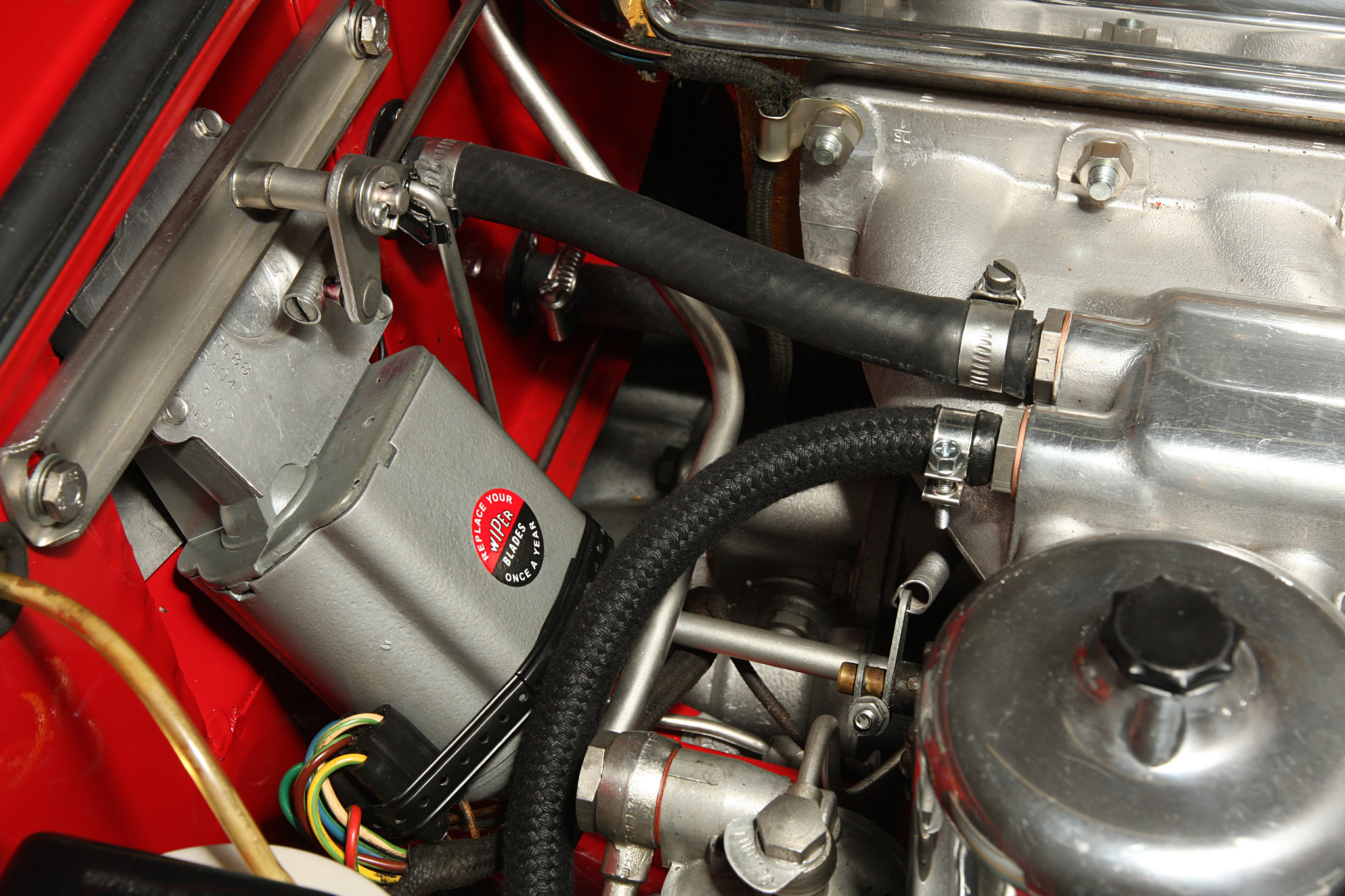

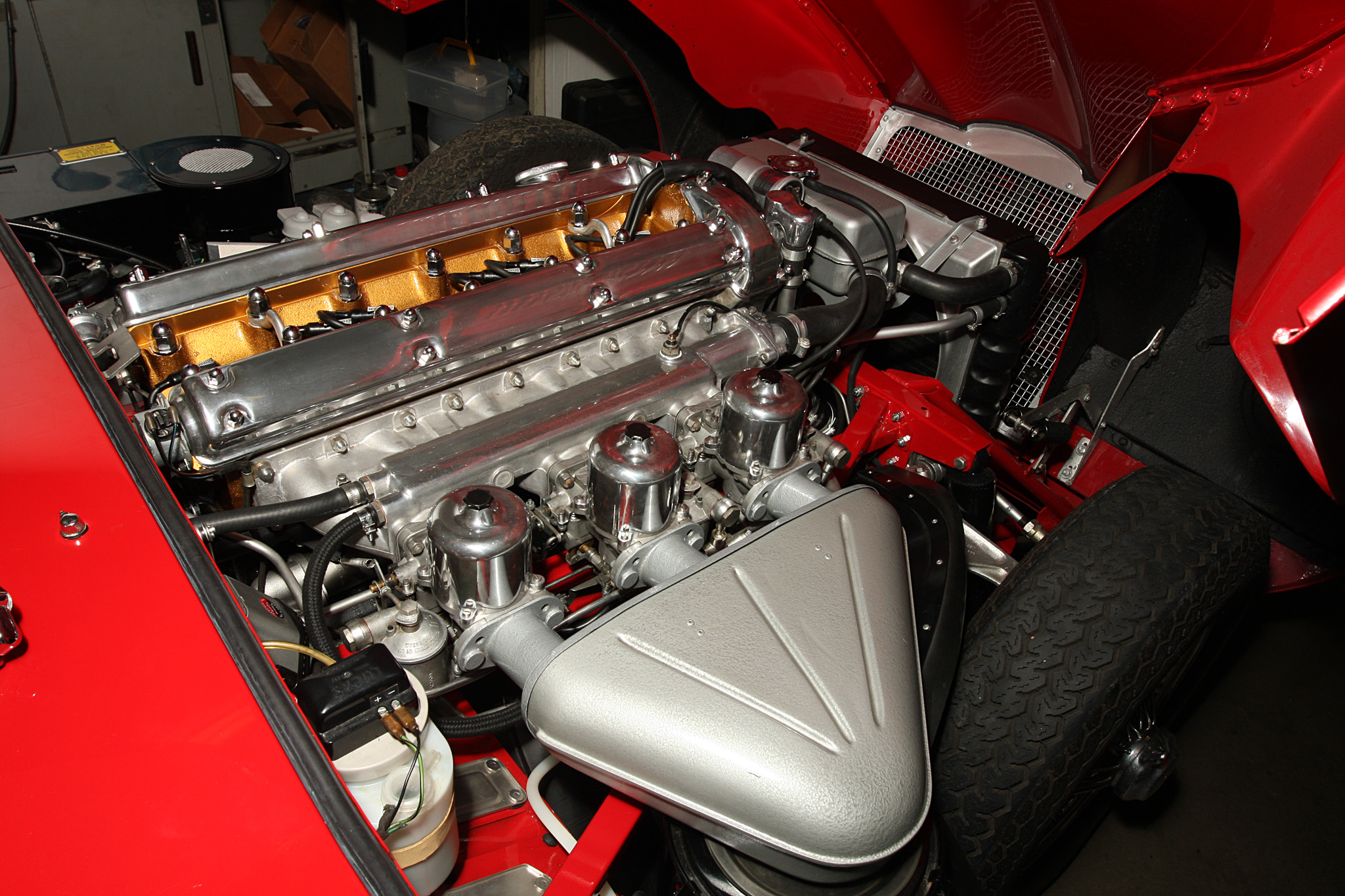

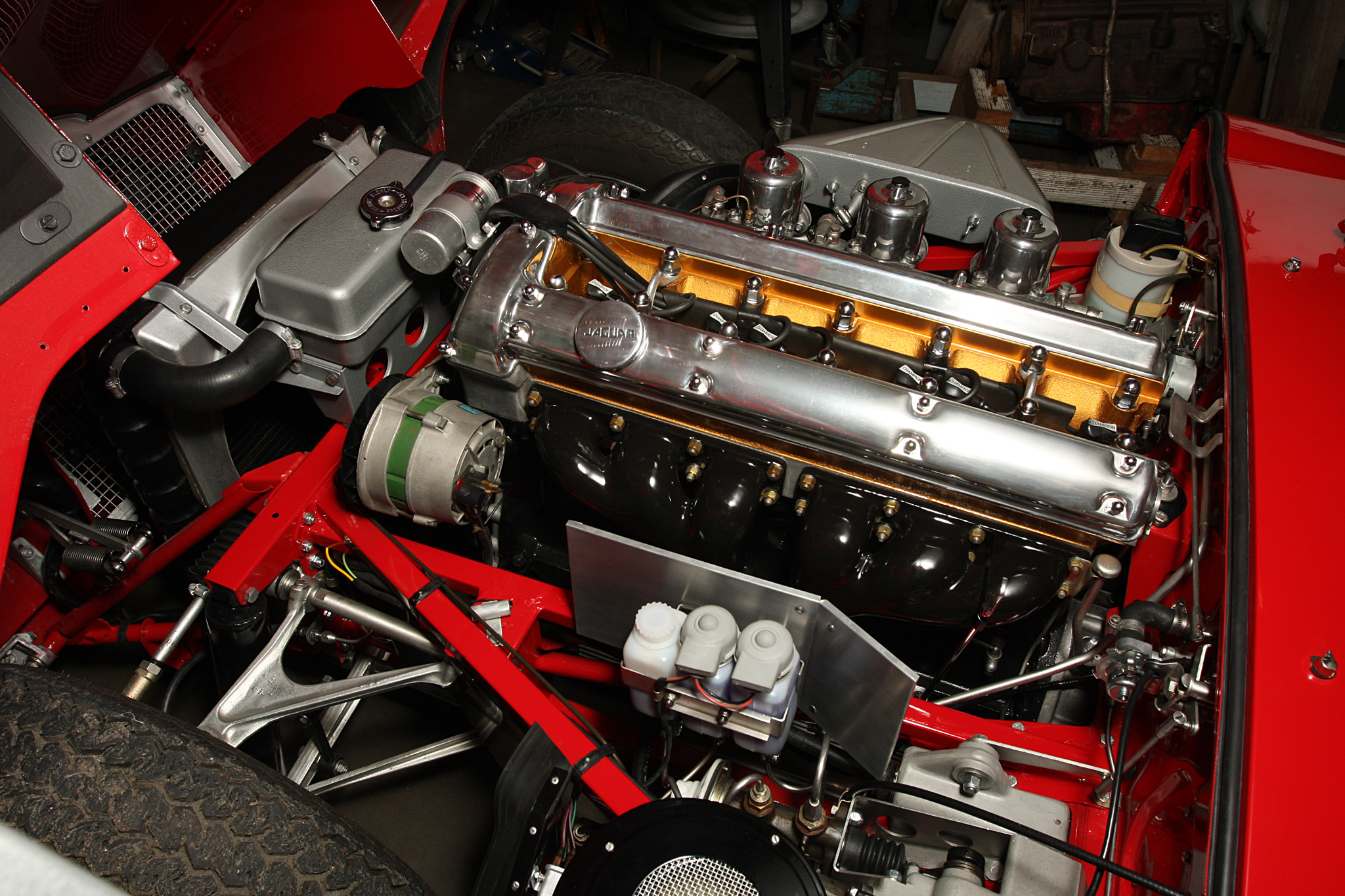

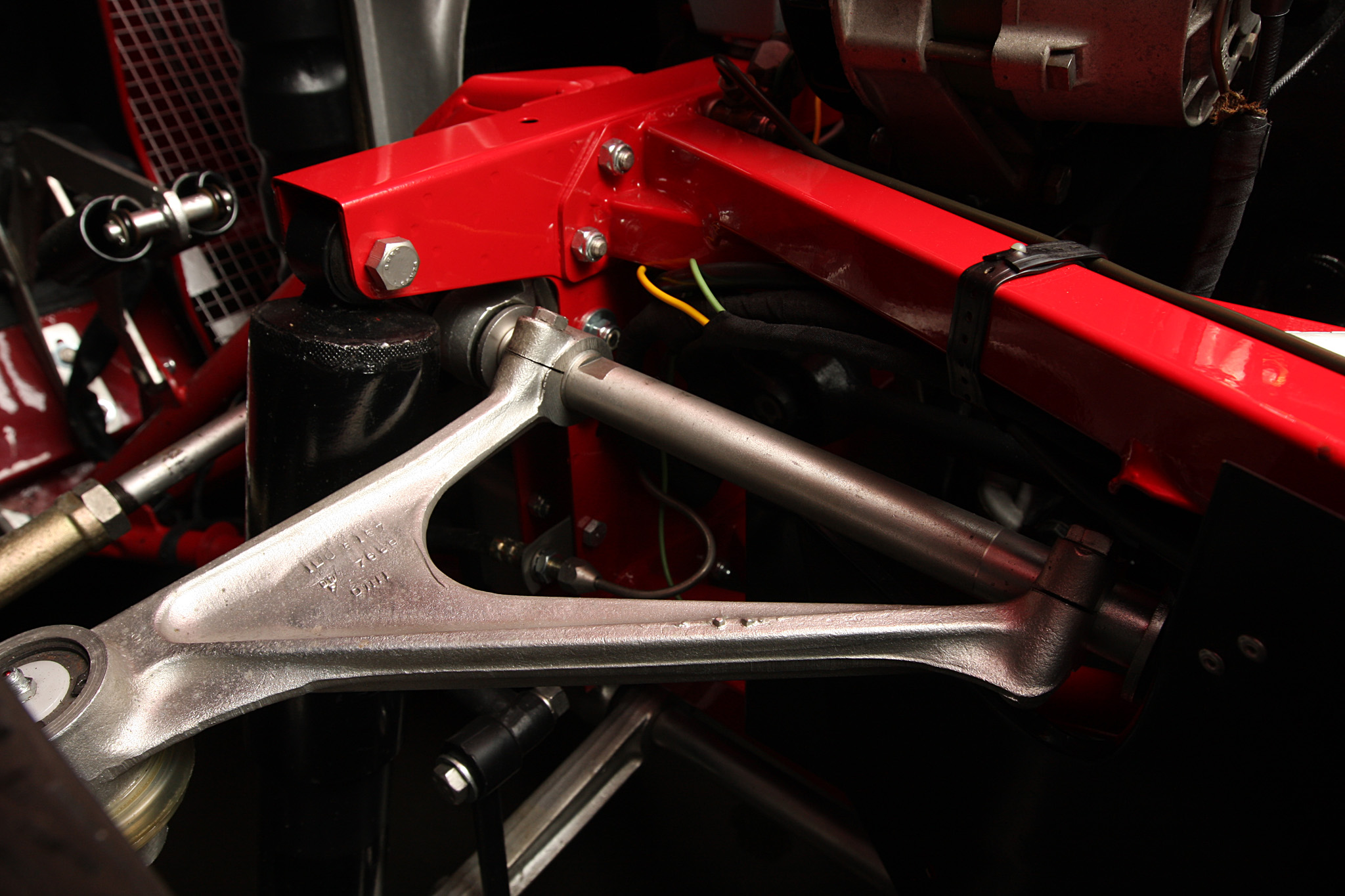

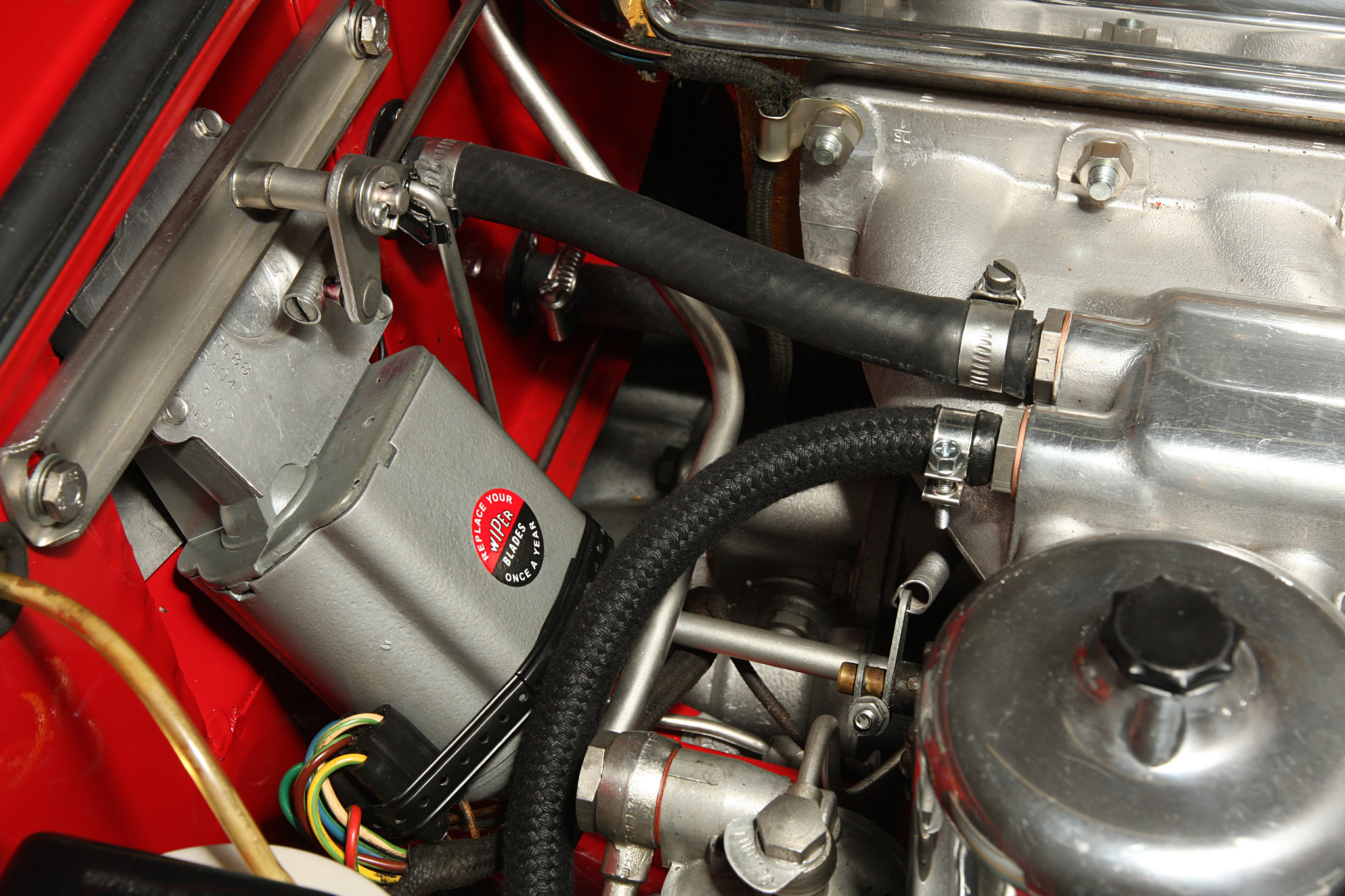

Here are some pictures of our finished E-Type project, the Italian Job which was ordered new from Italy.

Quite pleased with the result. It respects the original, out-of-the-box appearance which is quite enough bling for us.

Today we assembled the Tools for our 1954 MG TF restoration project. Many of these tuck into the ammunition box that is welded into the front firewall except the starting crank that is fastened to the rear bodywork.

Subtle details include an Enots grease gun with a Black Oxide/Blued barrel and the correct King Dick pliers with new wrinkle finish.

It took many talents to bring this kit together including a new roll from the The In-Point PTY Limited who manufacture a replica bag with the correct latex covered hessian/jute material.

A few of the items are original to the car and came in the ammunition box including 2 of the open spanners and all the box-spanners. Many of the scarcer items cam from Hugh Pite including the rare king dick feeler gauge, a short-handle ball peen hammer and an original King Dick jack with handle!

According the very excellent Original MGTF Midget website our kit is now very complete:

King Dick Ring-Type tappet spanner

King Dick Ring Spanner for cylinder head nuts

King Dick .019 Tappet Feeler Gauge

¾-pound ball peen hammer

King Dick Pliers

ENOTS No.1 Grease Gun

Two Dunlop Tire Levers

Tire Valve Spanner

Lucas Distributor Feeler and screwdriver

Screwdriver

Unlabelled Shelly-Type Tyre Pump

King Dick Set of Box Spanners

King Dick Set of Open Spanners

King Dick Adjustable spanner

King Dick 1077 Jack

King Dick Jack Handles

6-Inch Tommy Bar

THOR knock-off hammer

Here is the King Dick 1077 Jack sitting in its new home, the ammunition box fitted with white felt.

I think this is the last post before our MG TF is completely complete.

Fitted is the dashboard painted with the original colors found behind the dash with a lovely wheel by Ben Corsten/

The amount of upholstery work is tremendous for such a small car, so you’ll have to excuse us for more unlabelled photos. Much work has to be done for a Christmas delivery yet!