Tag Archiv: 1E31166

Here are some pictures of our finished E-Type project, the Italian Job which was ordered new from Italy.

Quite pleased with the result. It respects the original, out-of-the-box appearance which is quite enough bling for us.

A little over two weeks into our E-Type reconstruction has yeilded some quick results.

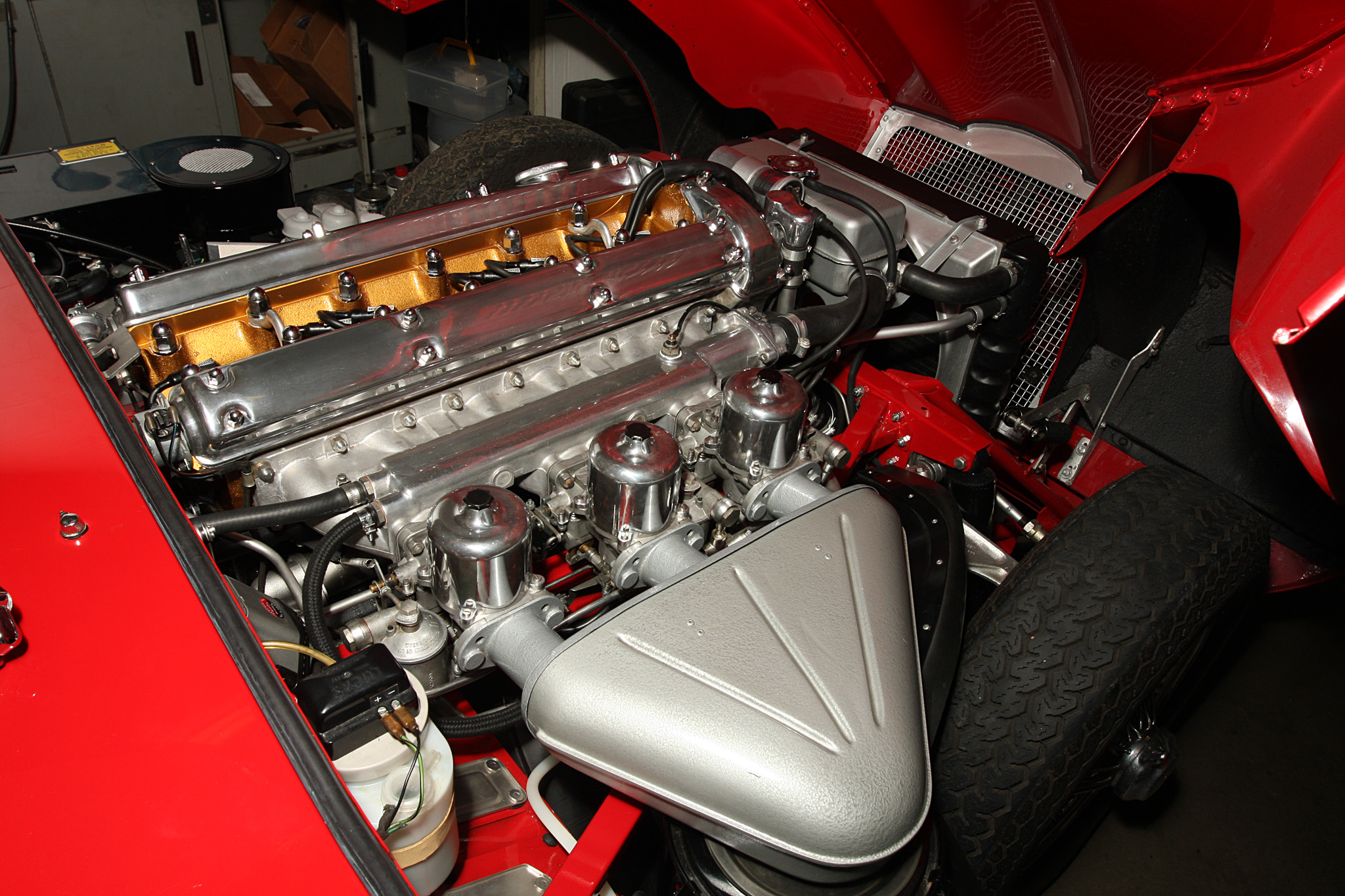

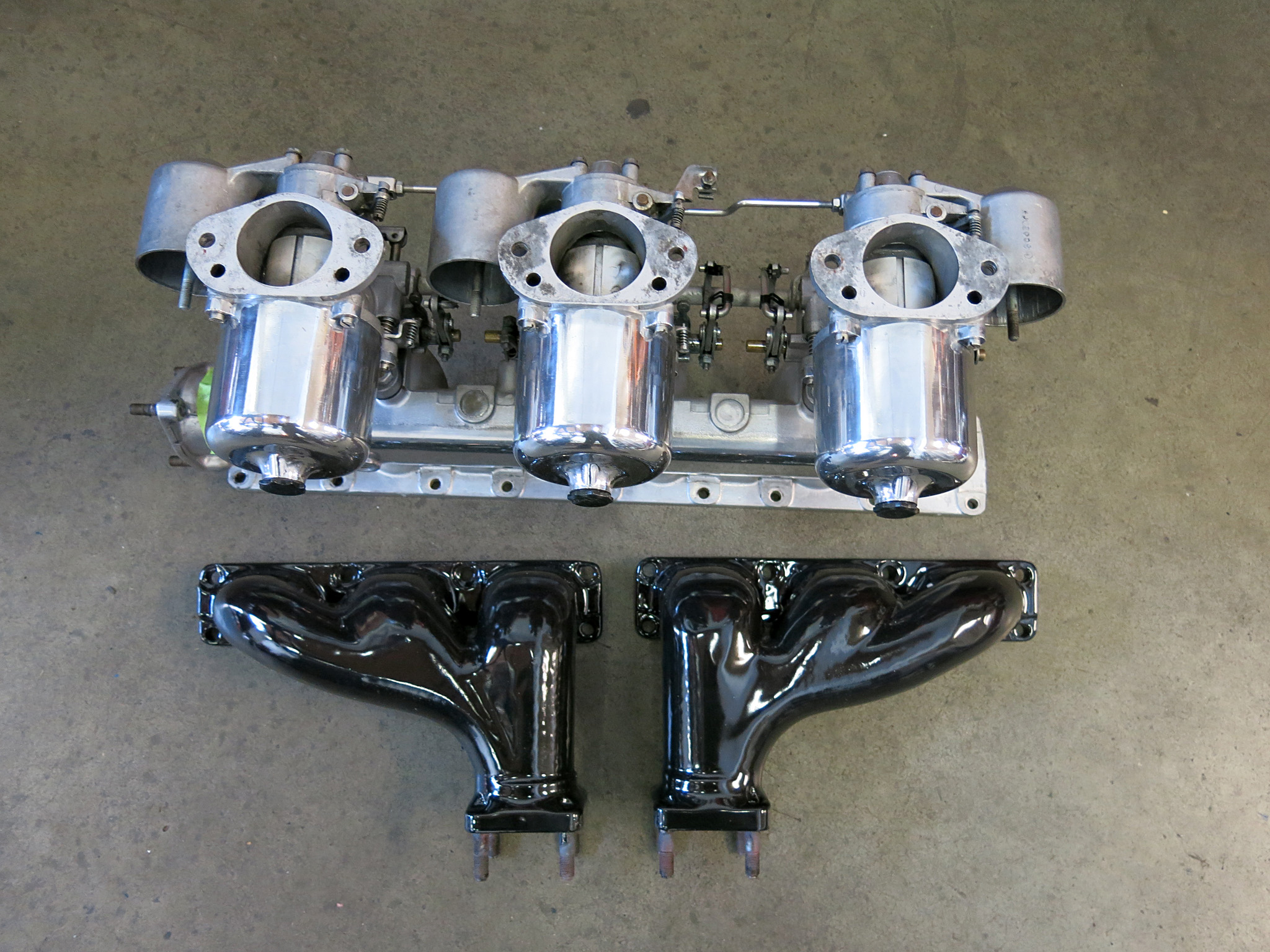

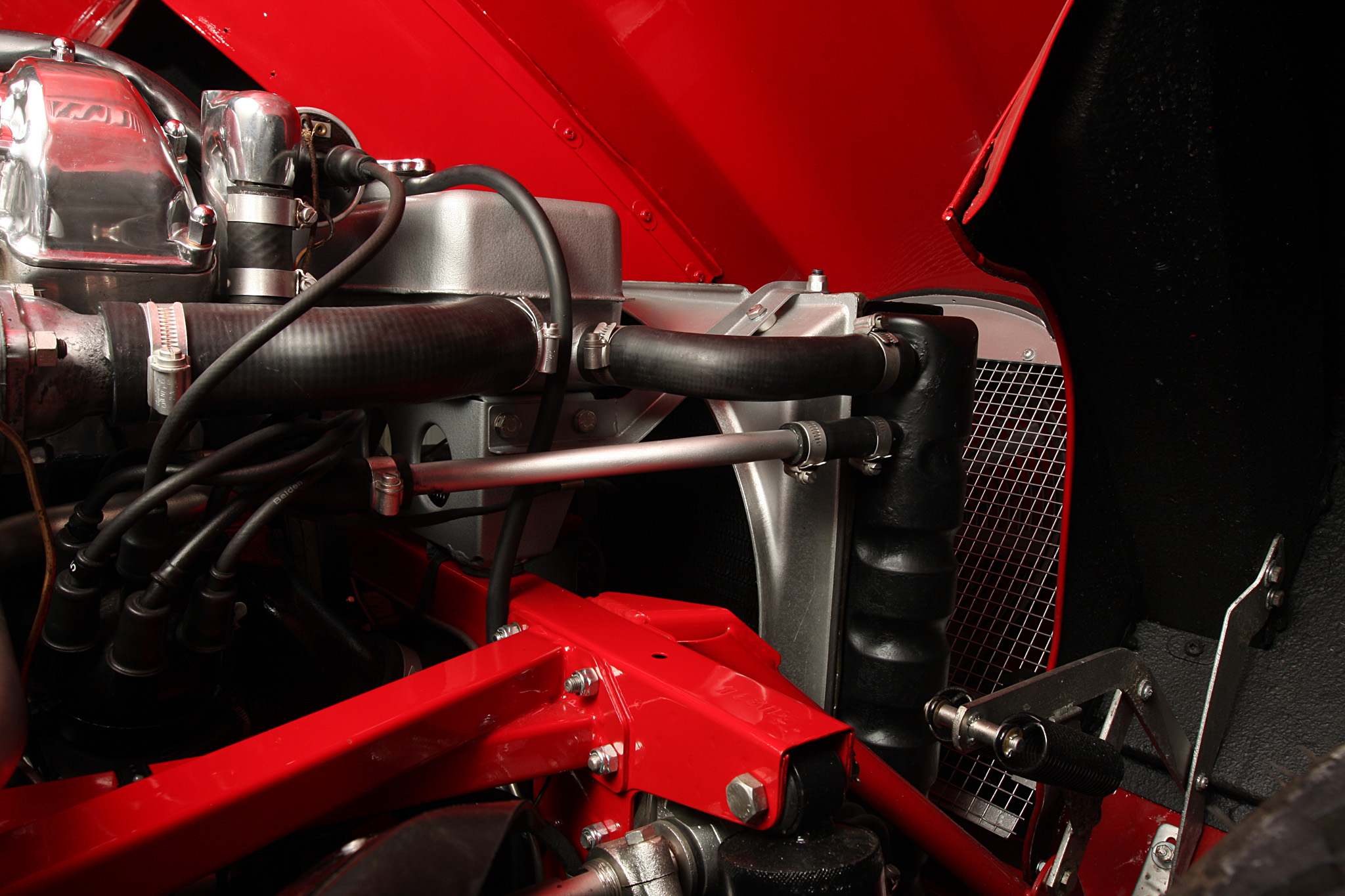

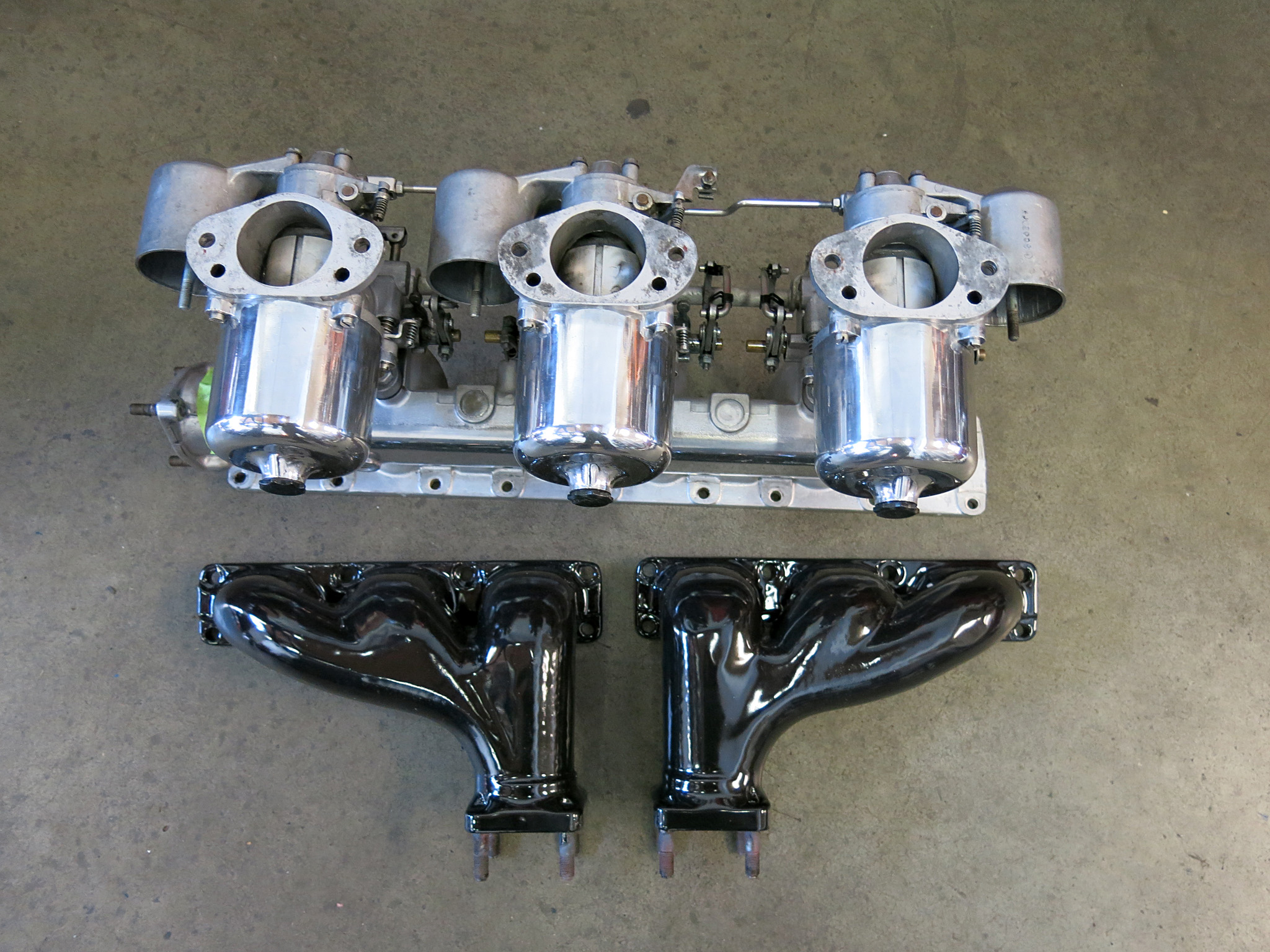

Fitted is the complete exhaust and intake systems including the Porcelain-coated manifolds that distinguish this build from most.

Not pictured is the fabled reaction plate install which was accelerated by releasing all the tension on the arms and wiggling the four bolts through by hand.

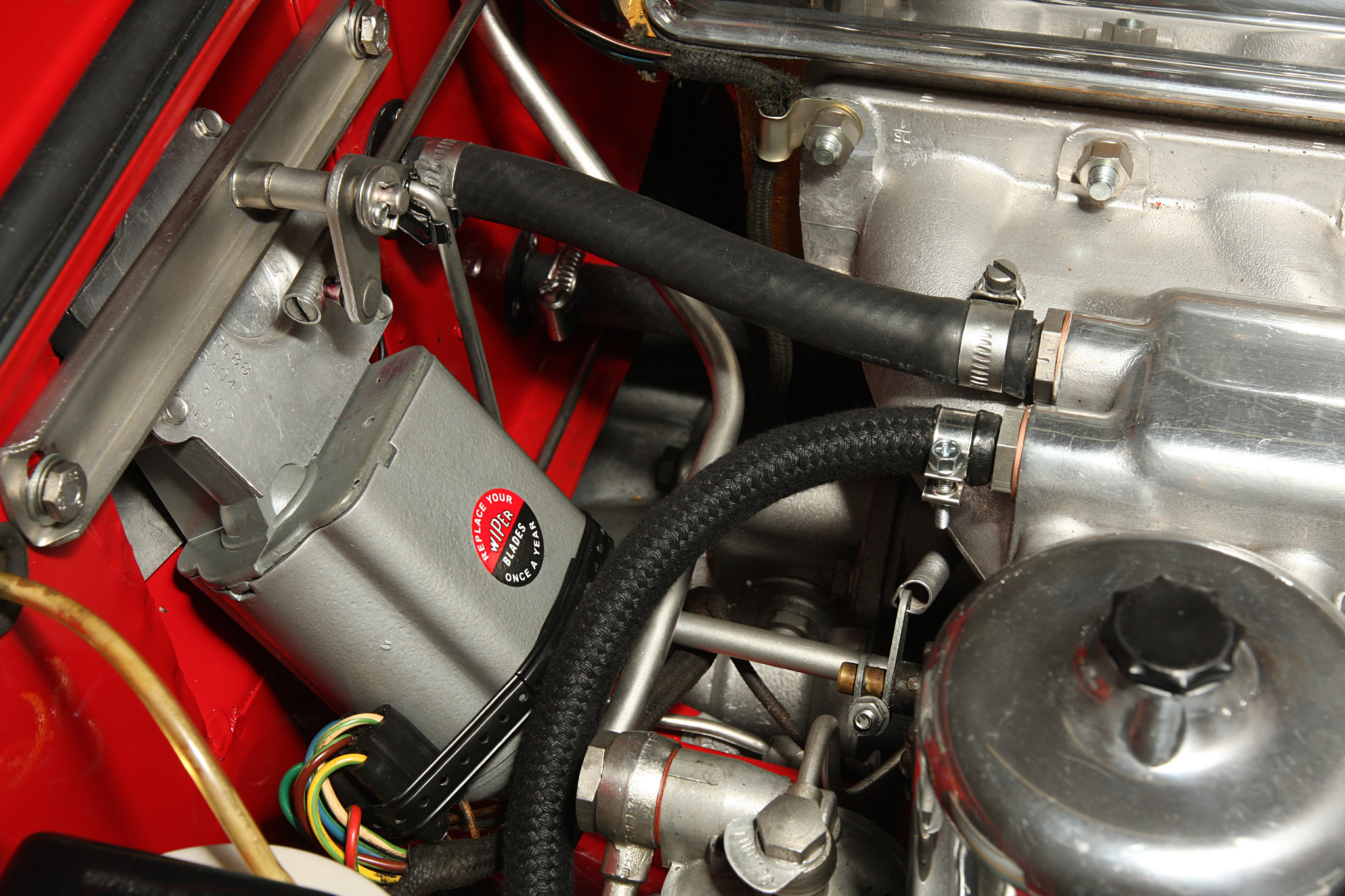

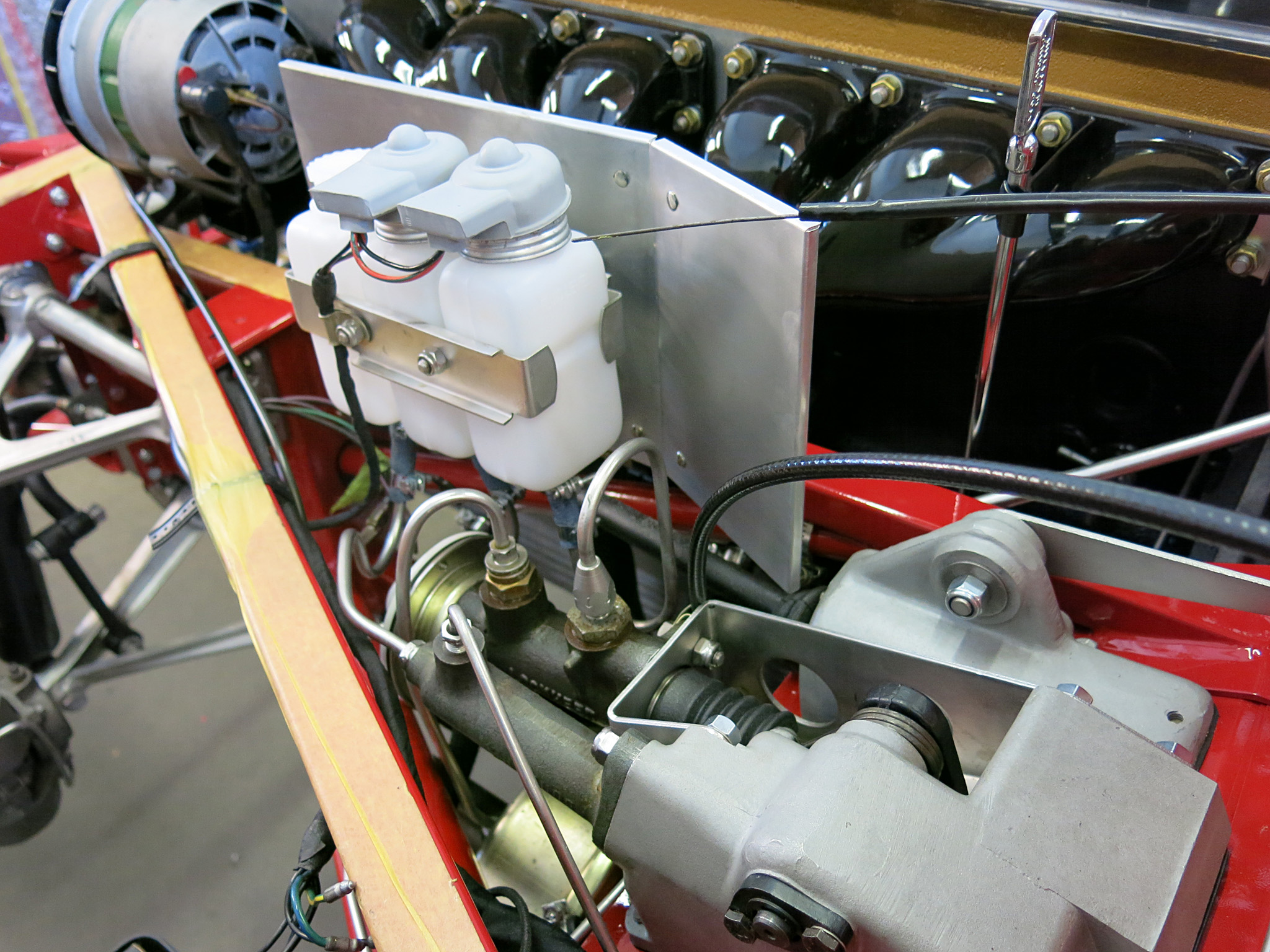

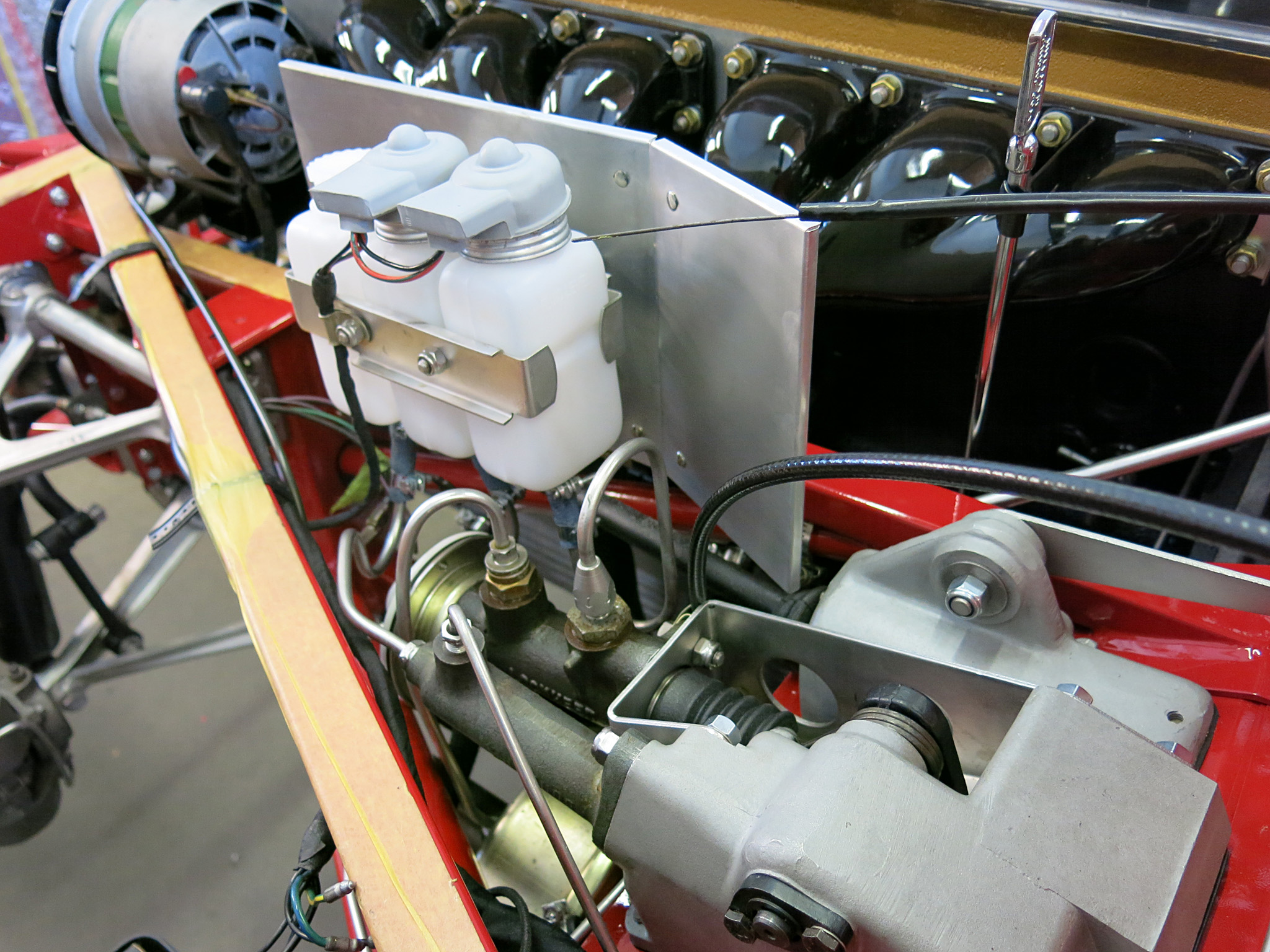

What else can I say. Oh yea the complete rebuild of the hydraulic brake system took a little time too.

Italian Job is back in the shop!

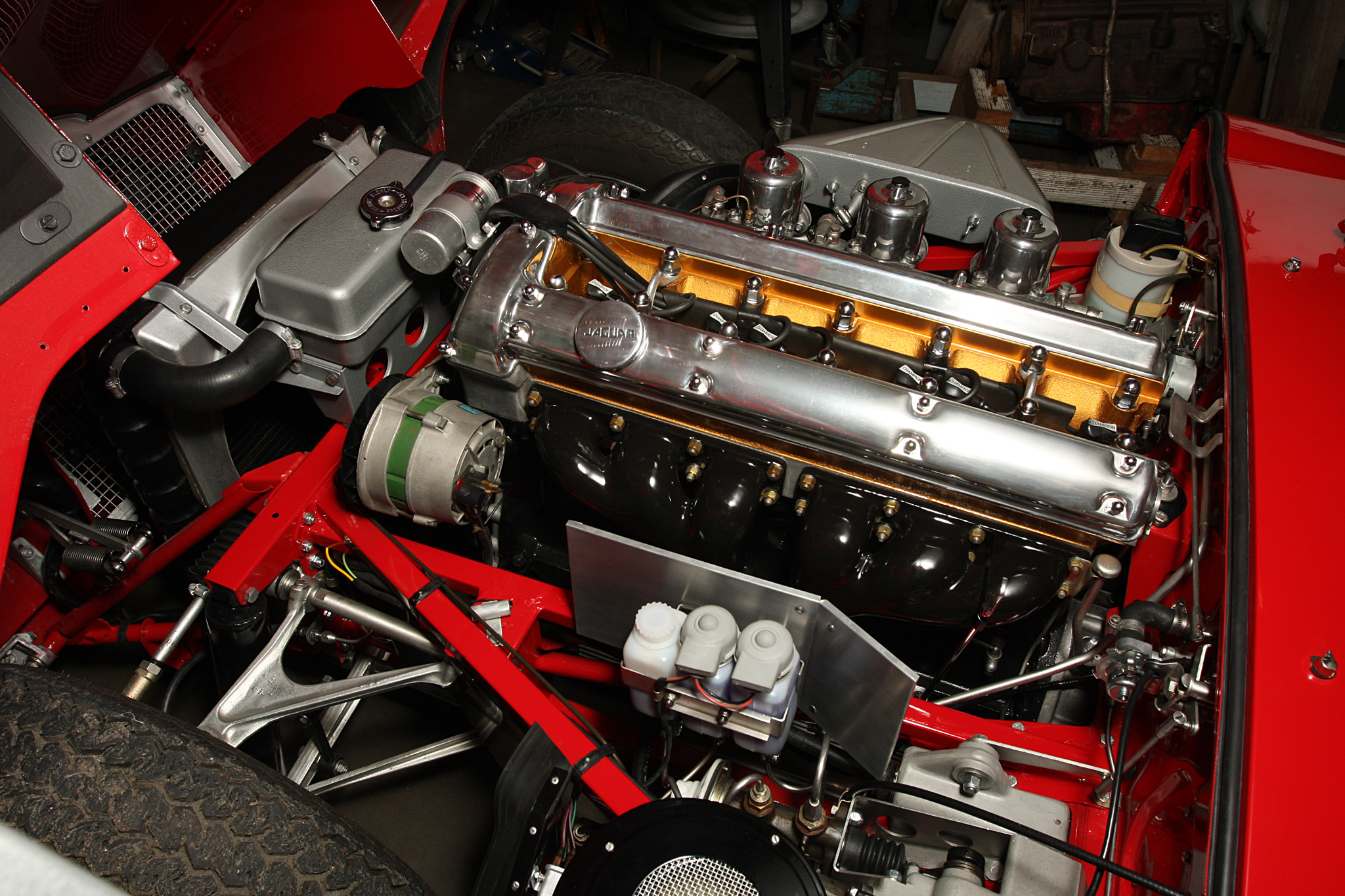

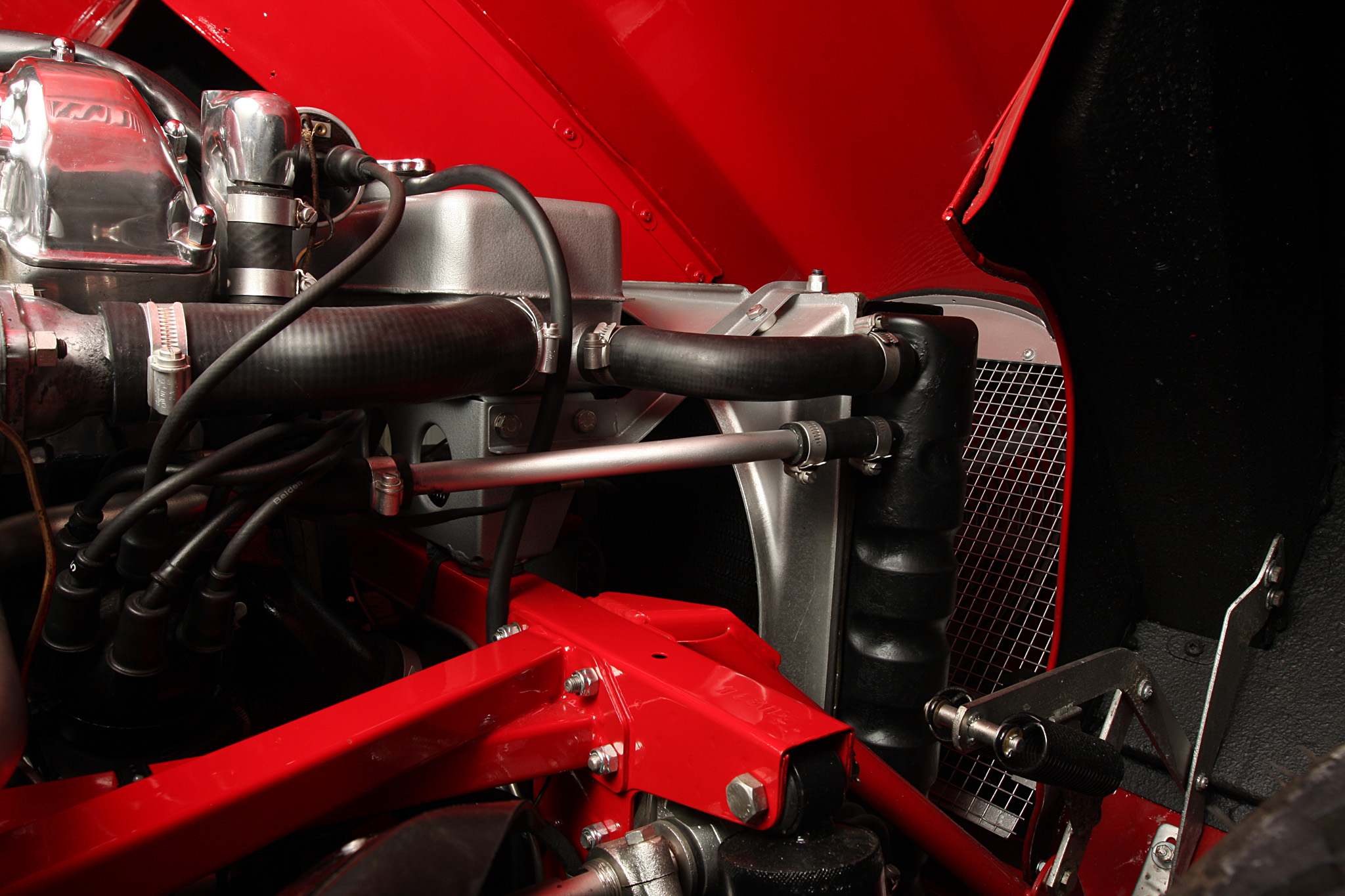

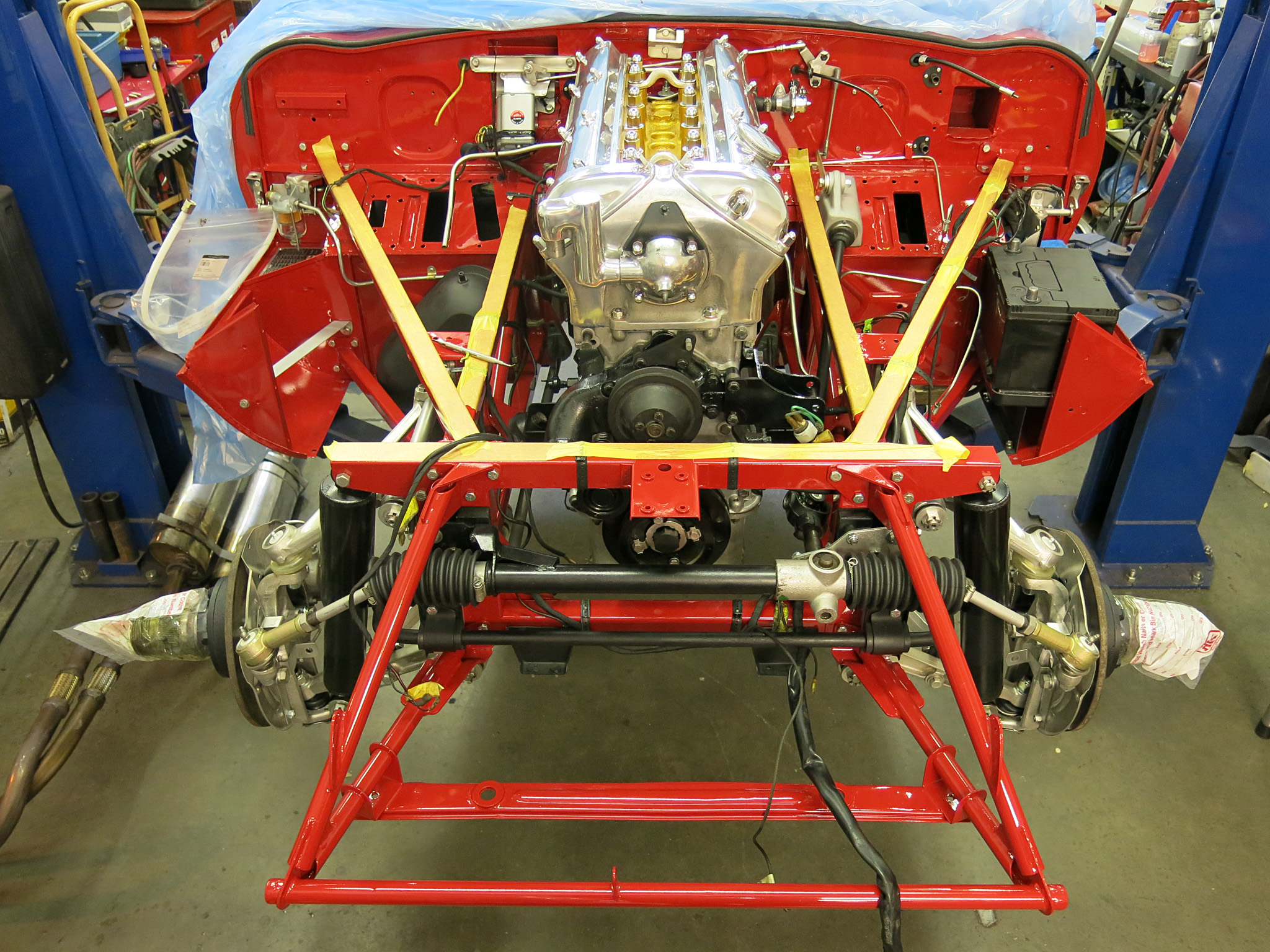

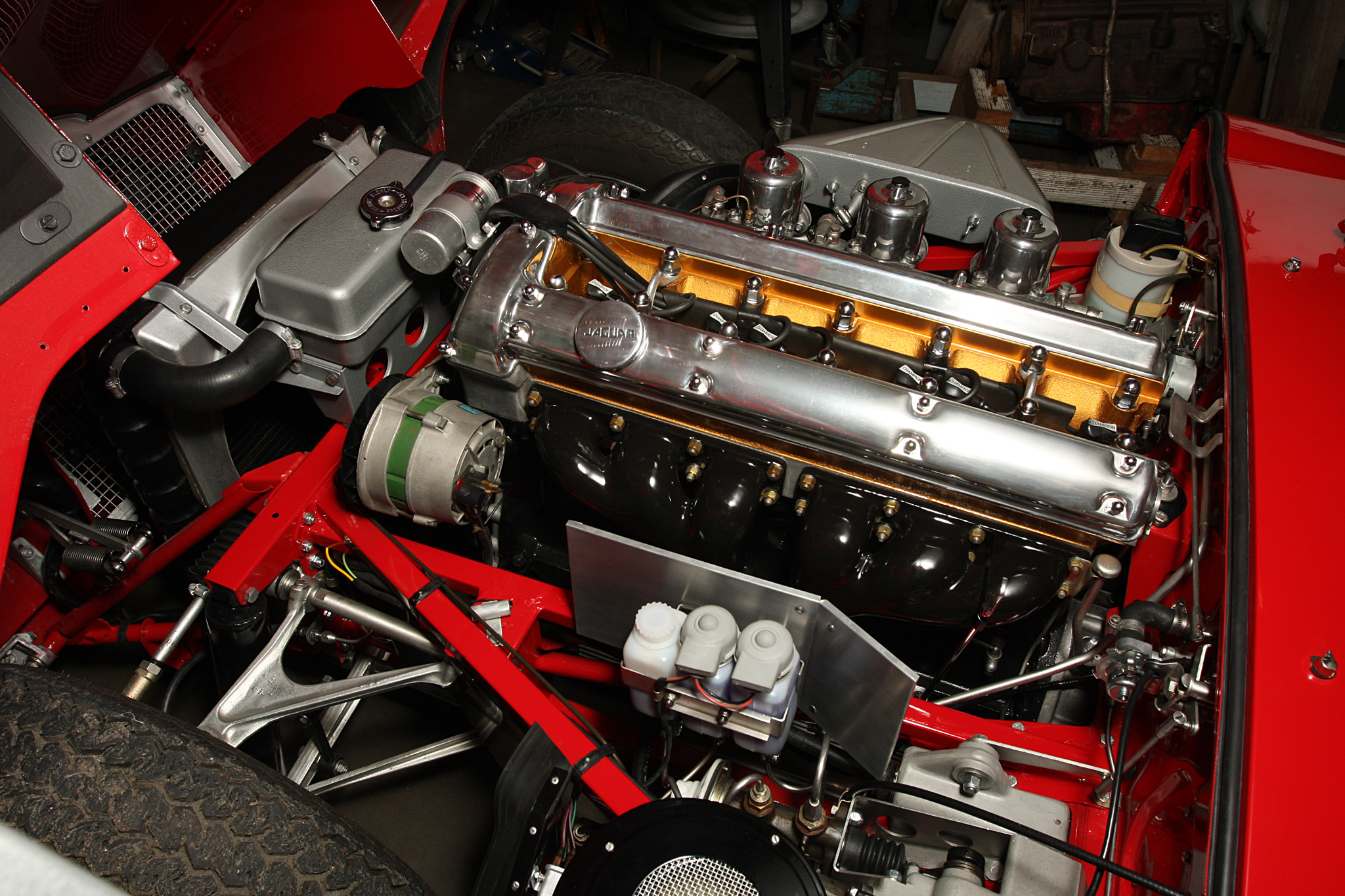

Here is 1 week’s progress. The 4.2 lump is back in and the accessories can now get piled on.

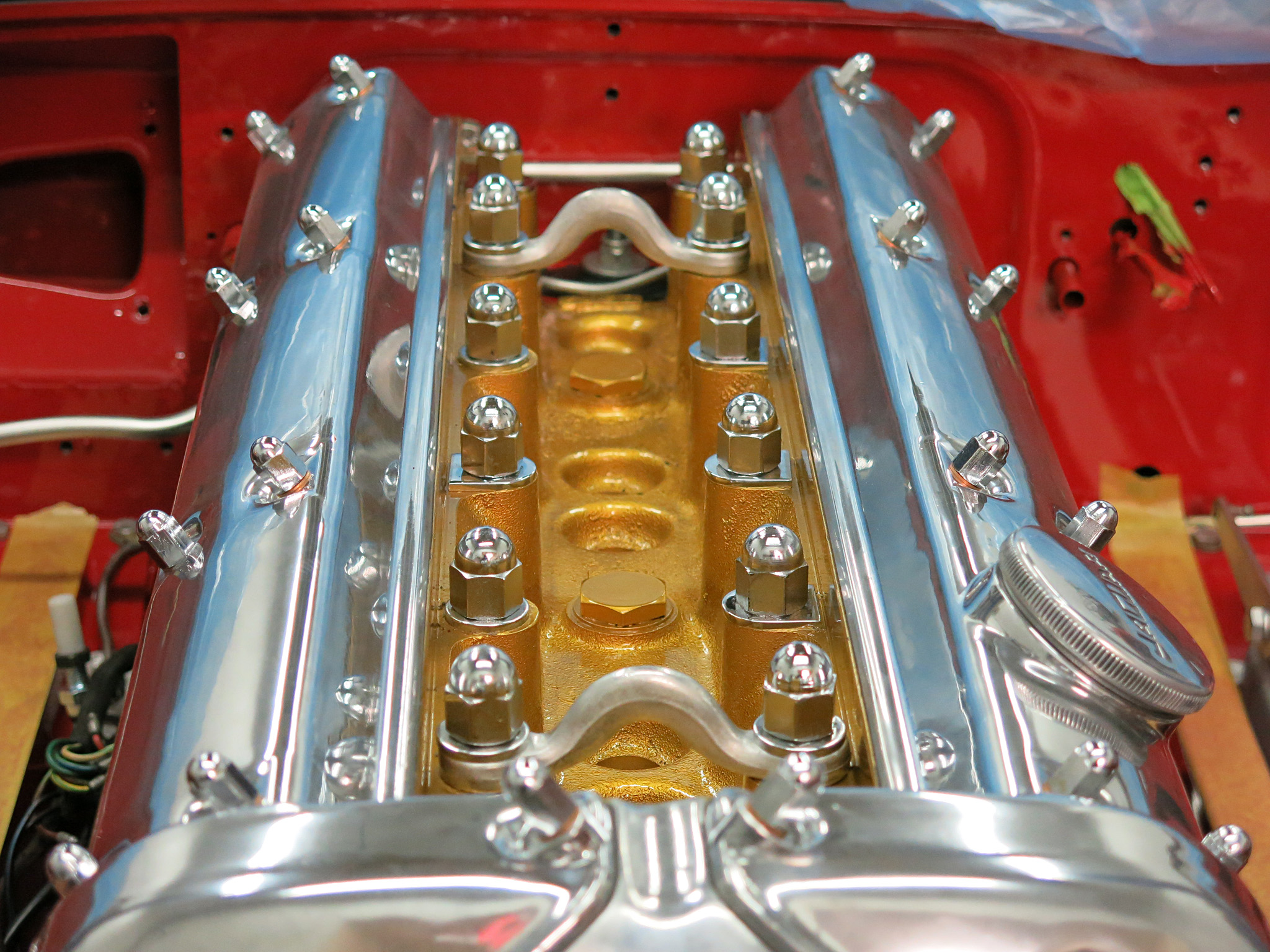

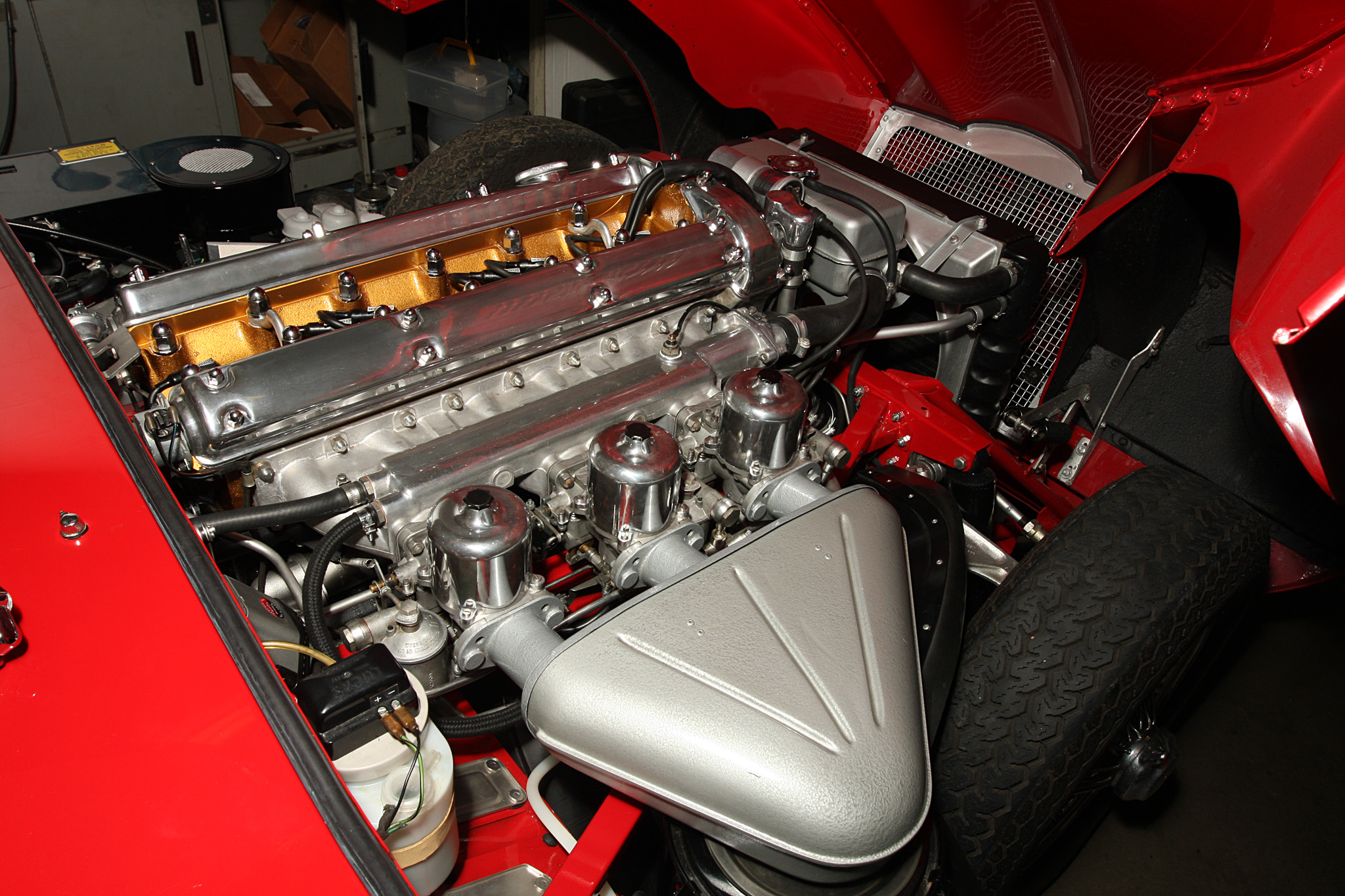

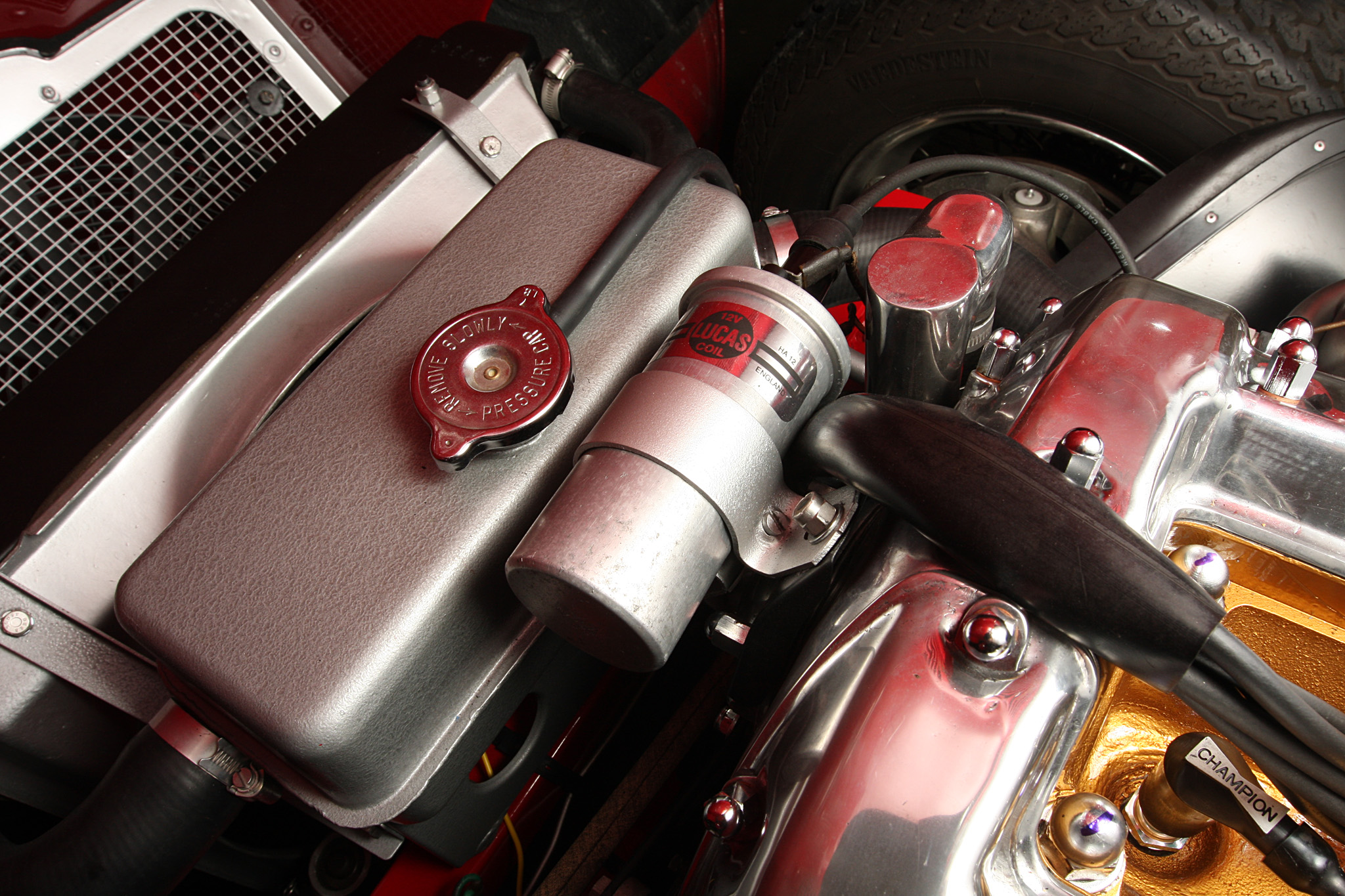

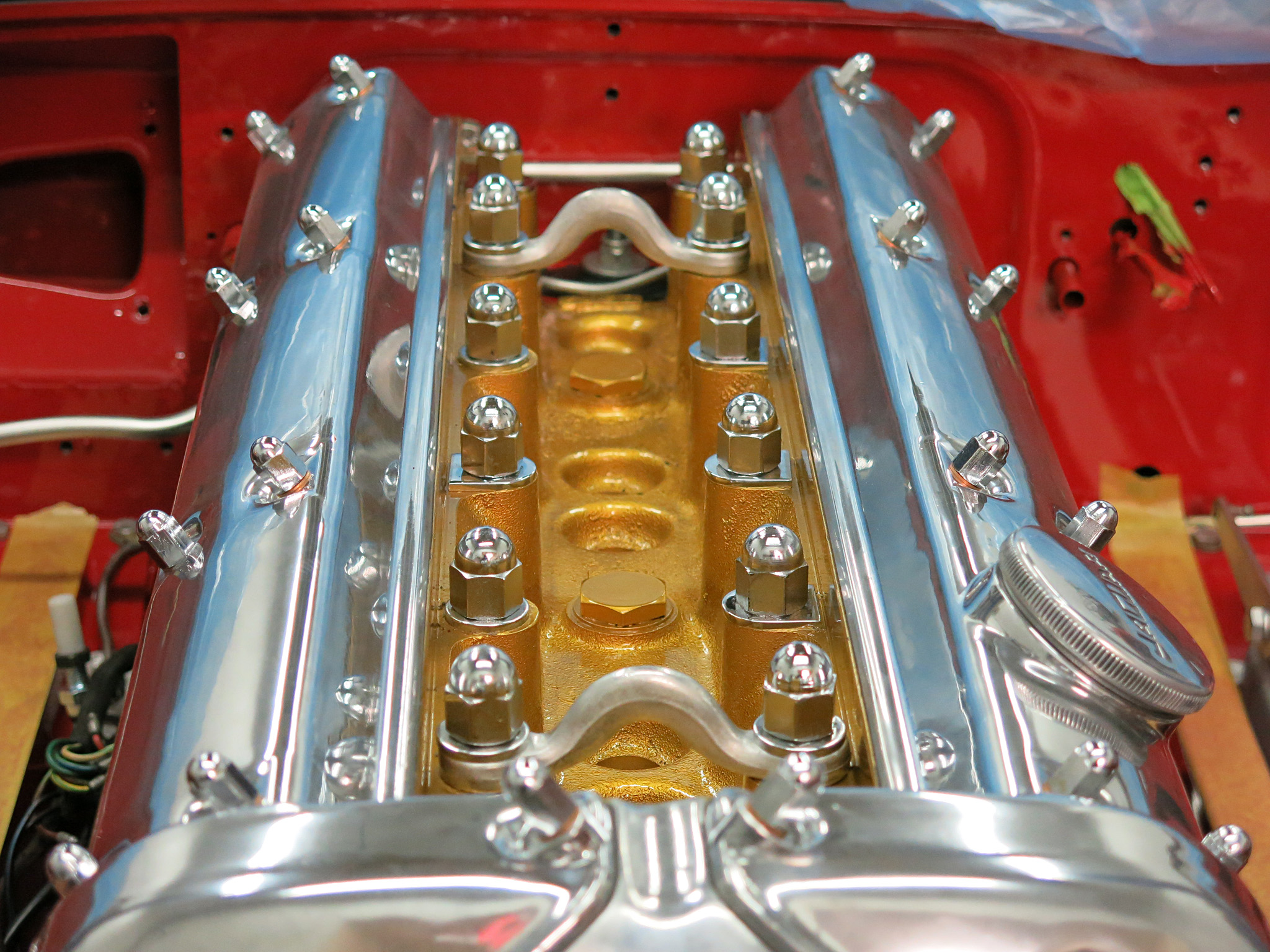

In many ways the E-Type engine bay was designed to look as good as it ran.

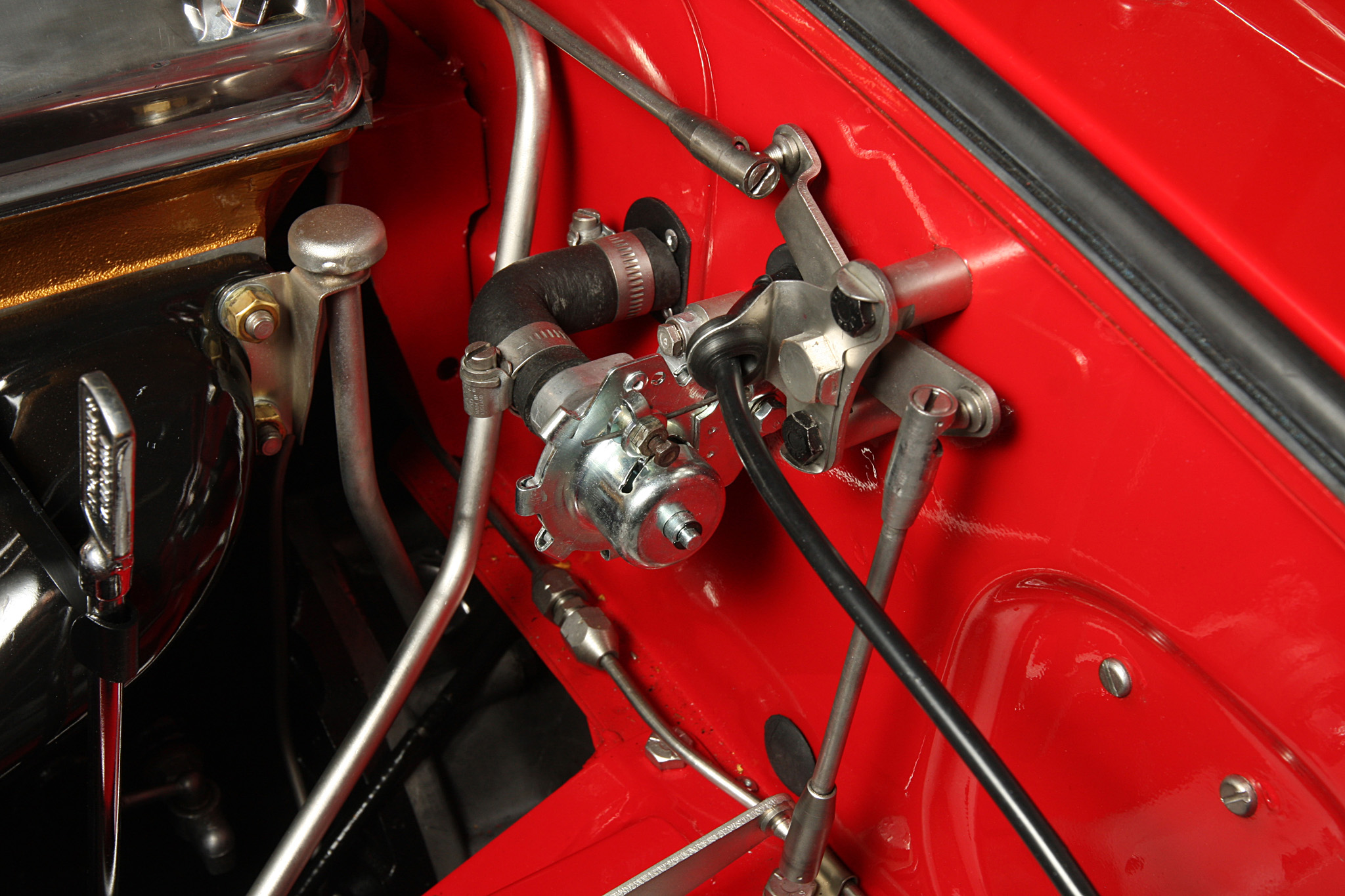

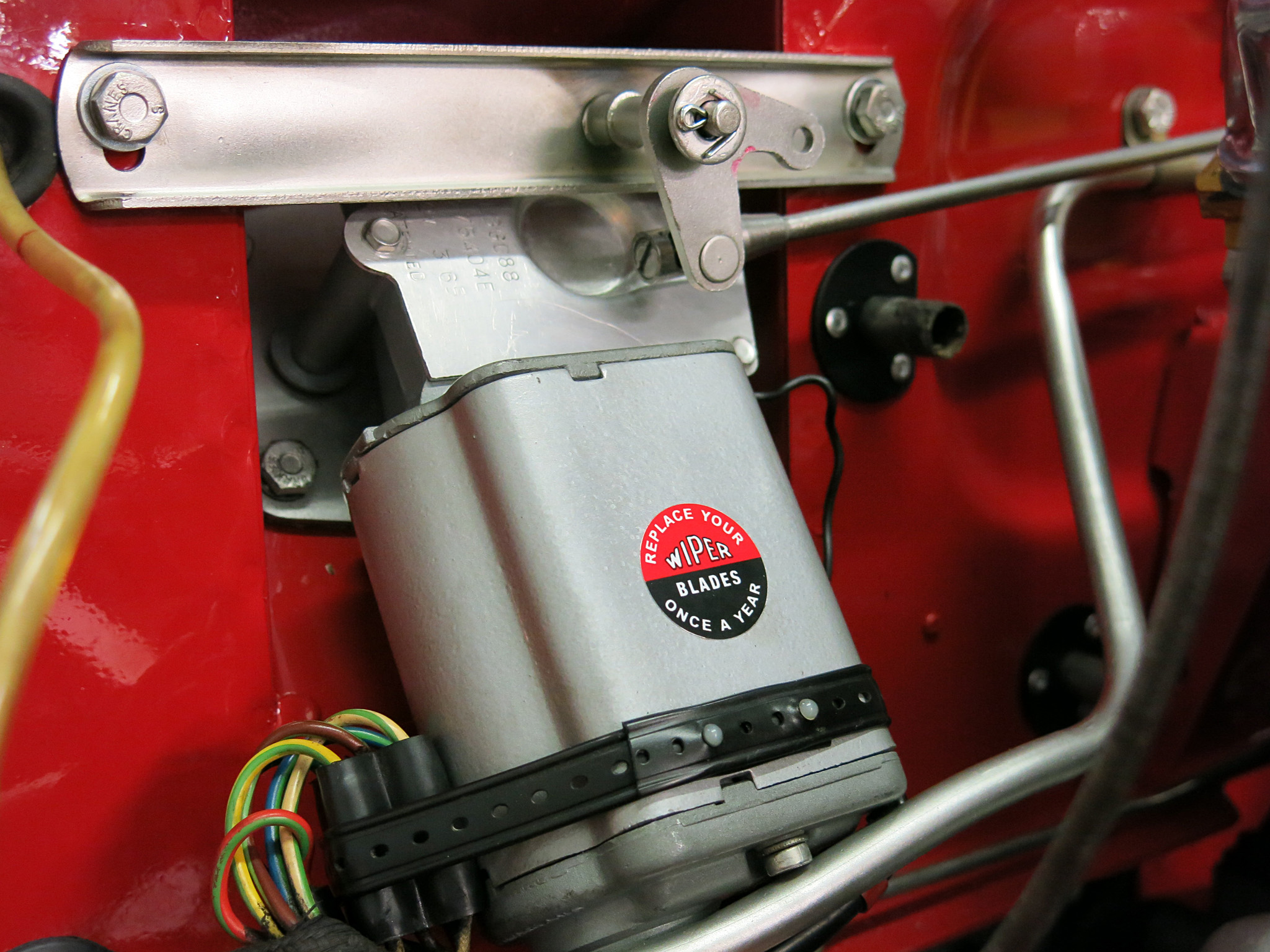

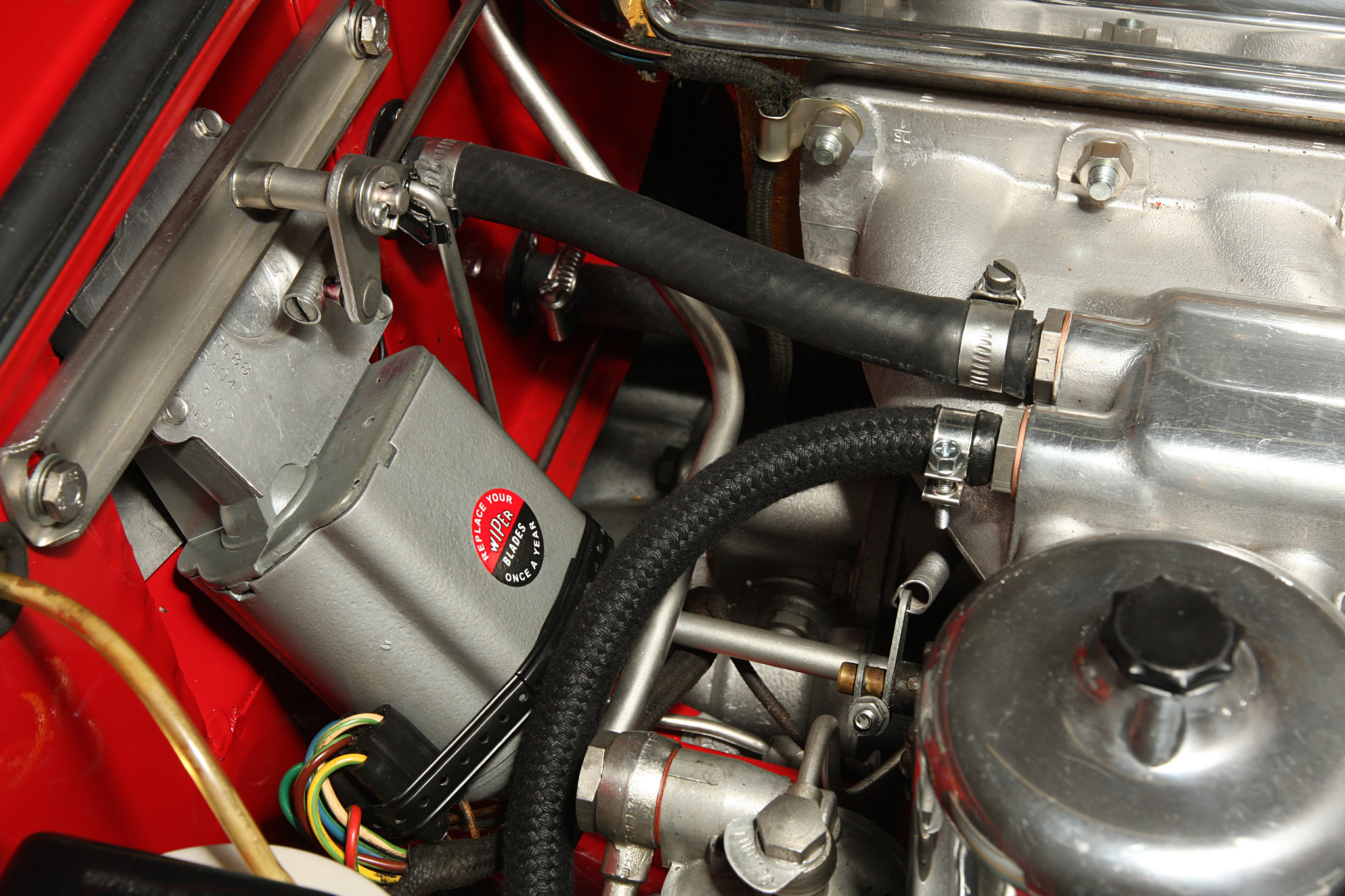

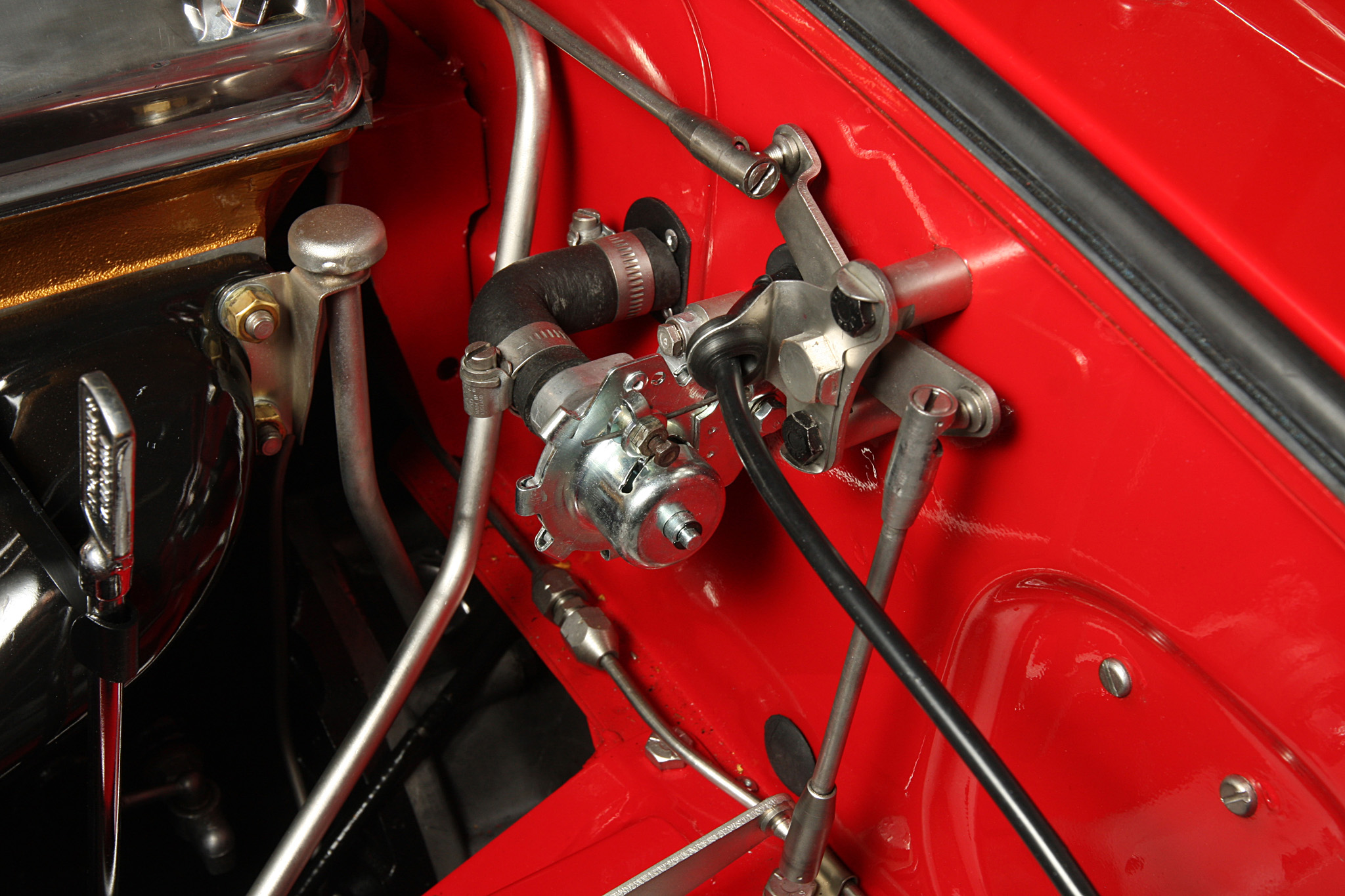

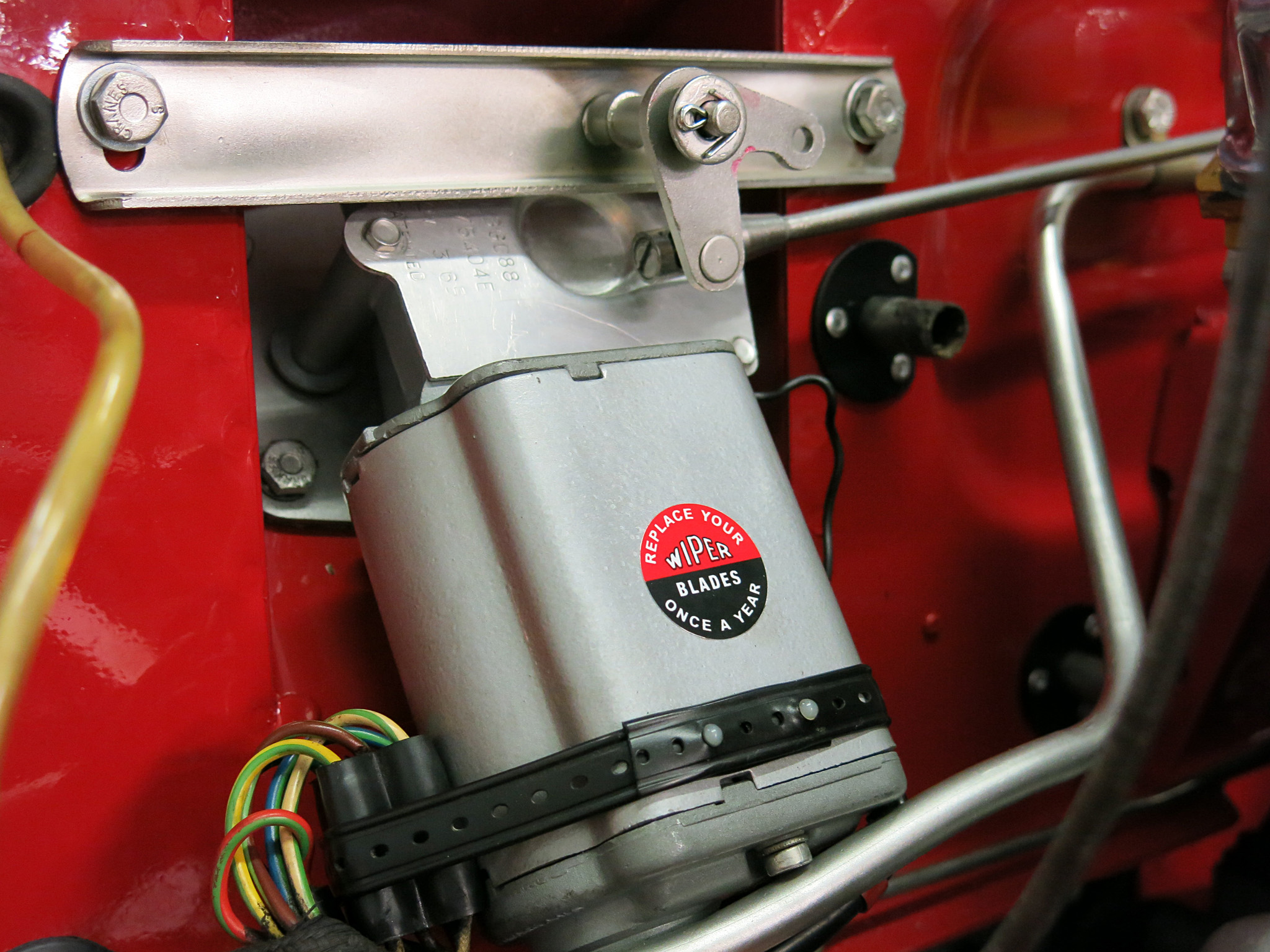

With the engine in we could route the electric wires on the subframe then start on the firewall bits.

The Italian Job, our 1965 E-Type restoration has been compartmentalized over the last month while we wait to receive the car back.

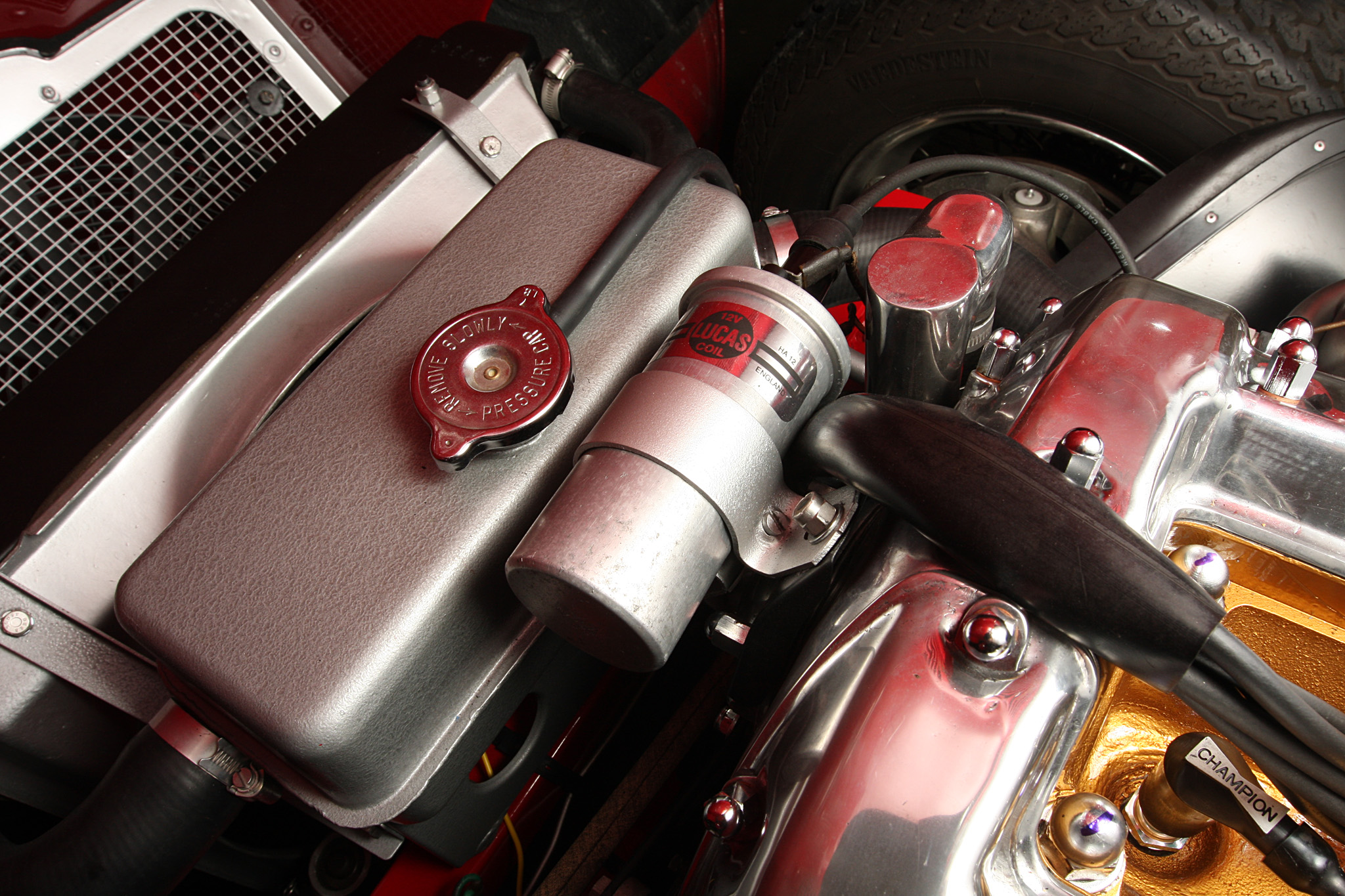

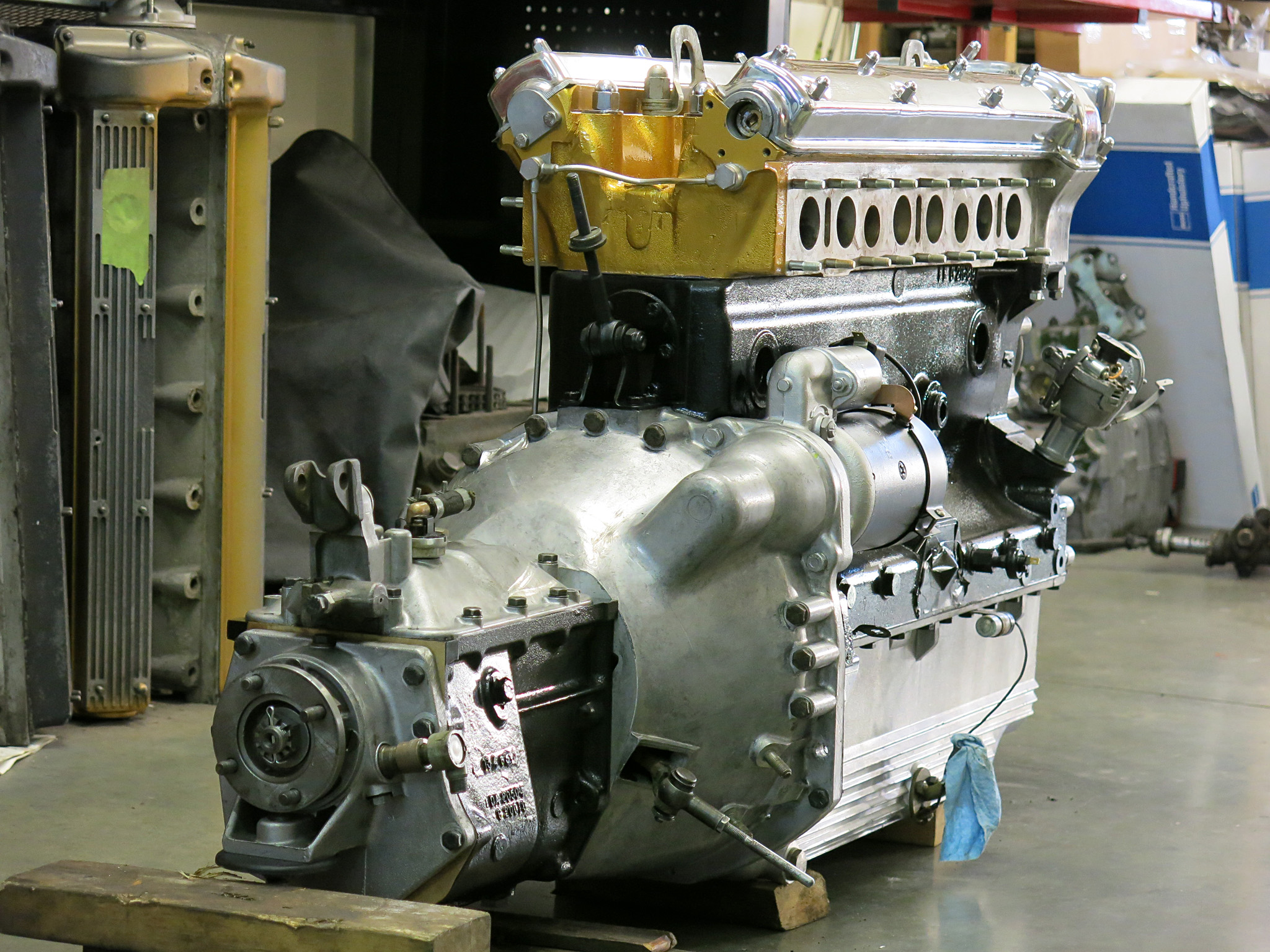

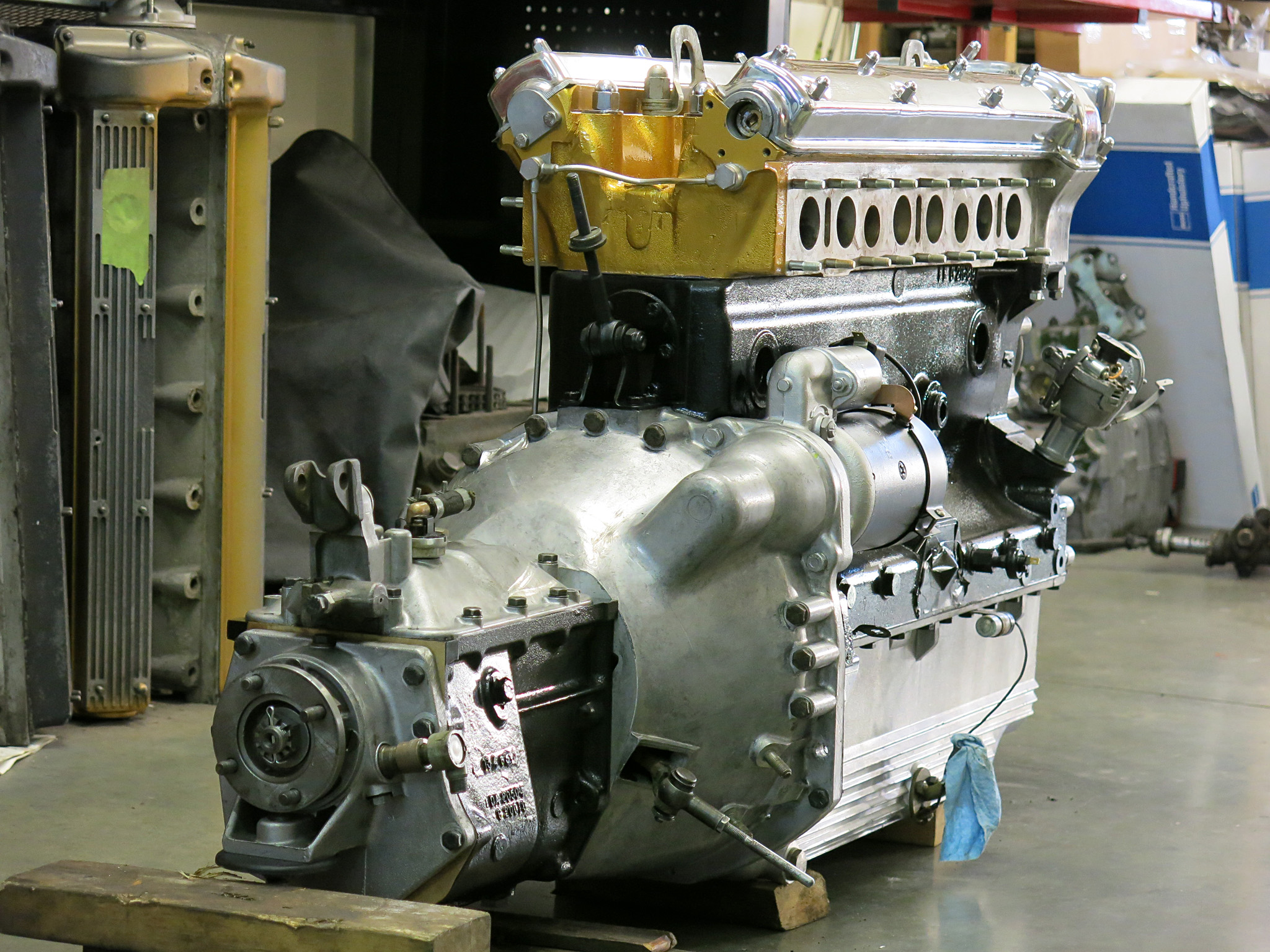

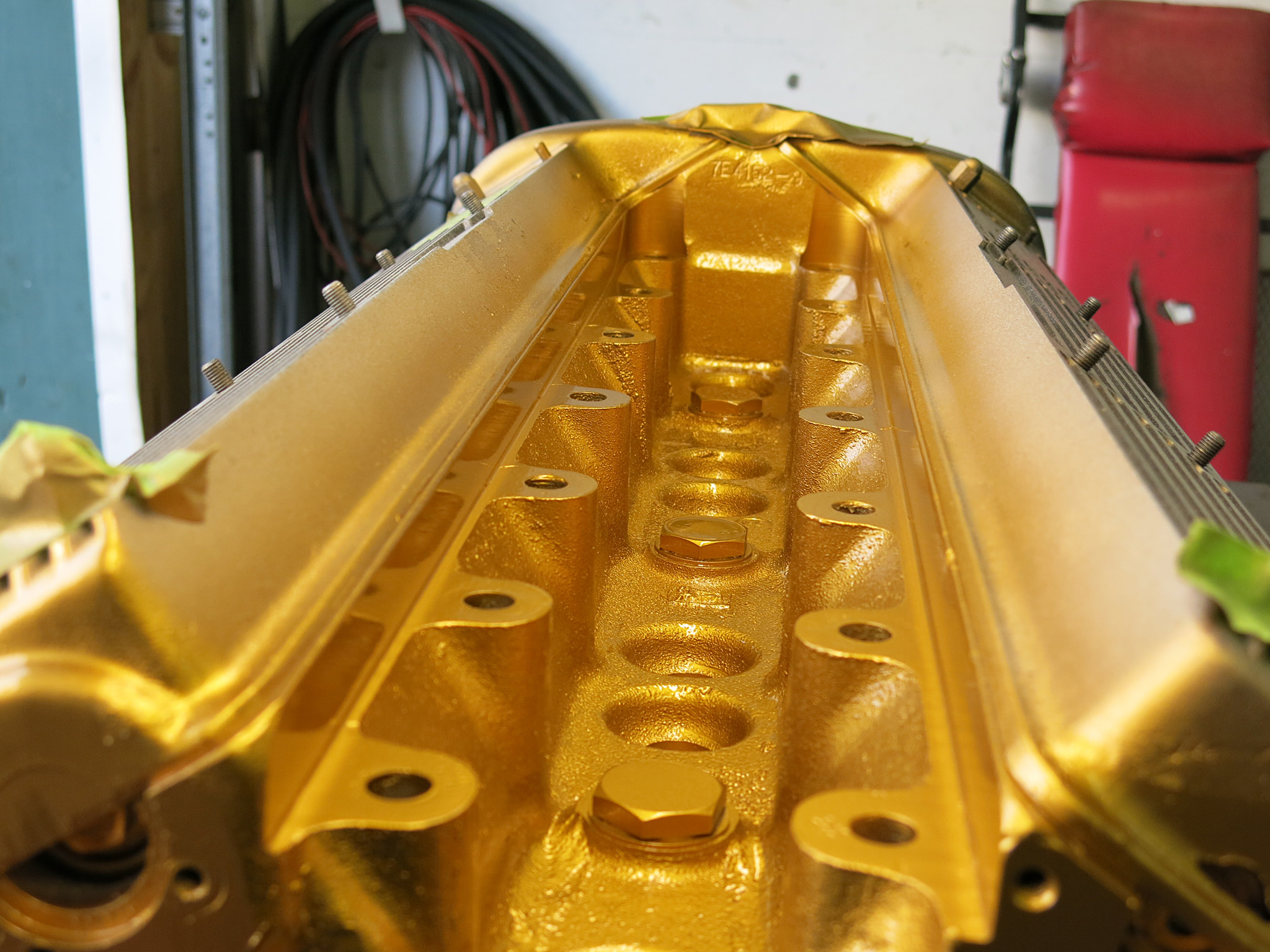

This left the enormous task of tackling the 4.2 engine which meant a proper seal, paint and polish before marrying it back into the chassis. We fit new engine and transmission seals, a 3-piece clutch kit, frost plugs as well as re-machined the cylinder-head deck and flywheel. The starter motor was also expertly overhauled by Brian Roberts Auto Electric which is all too easy while the engine is out.

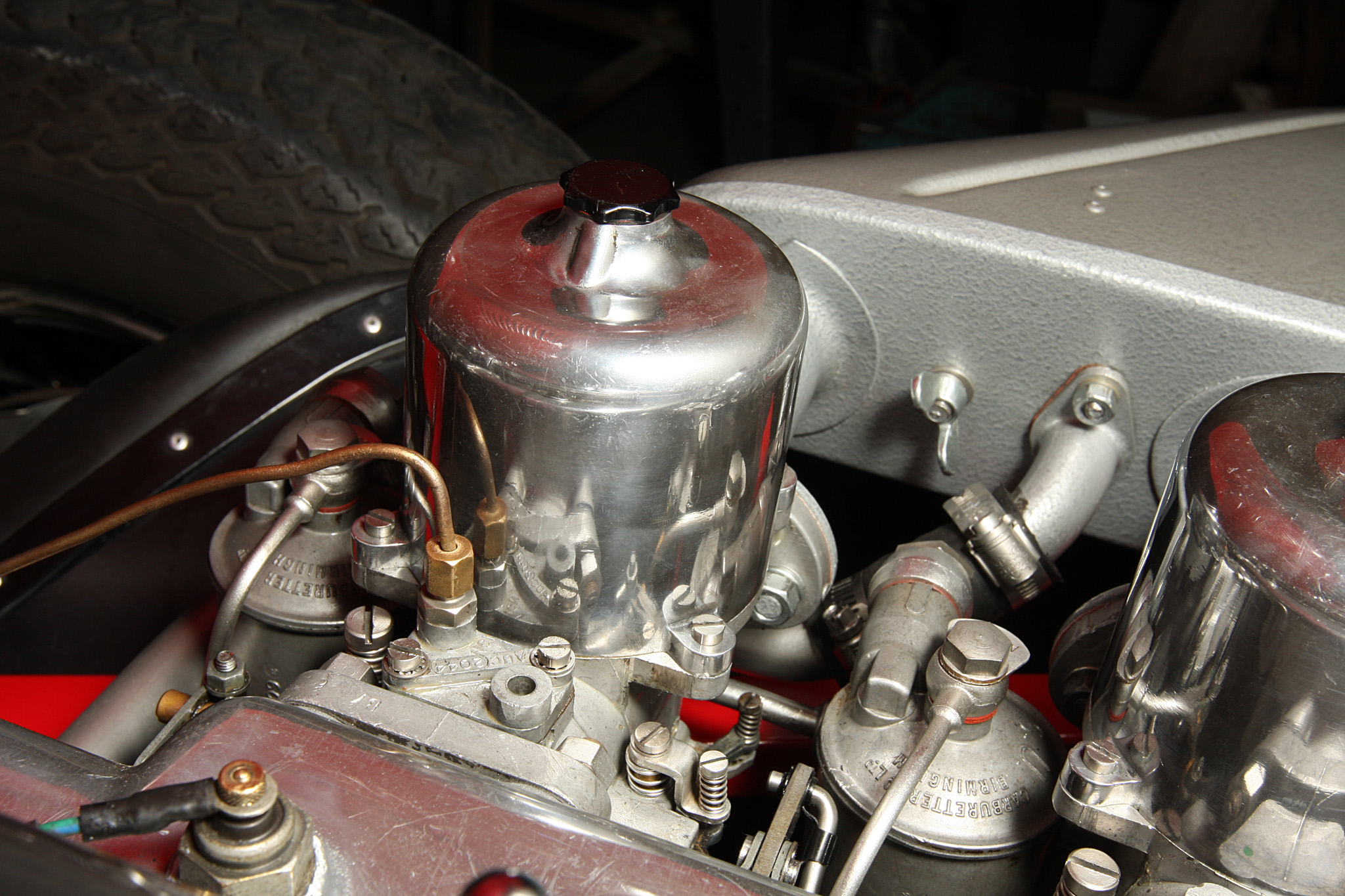

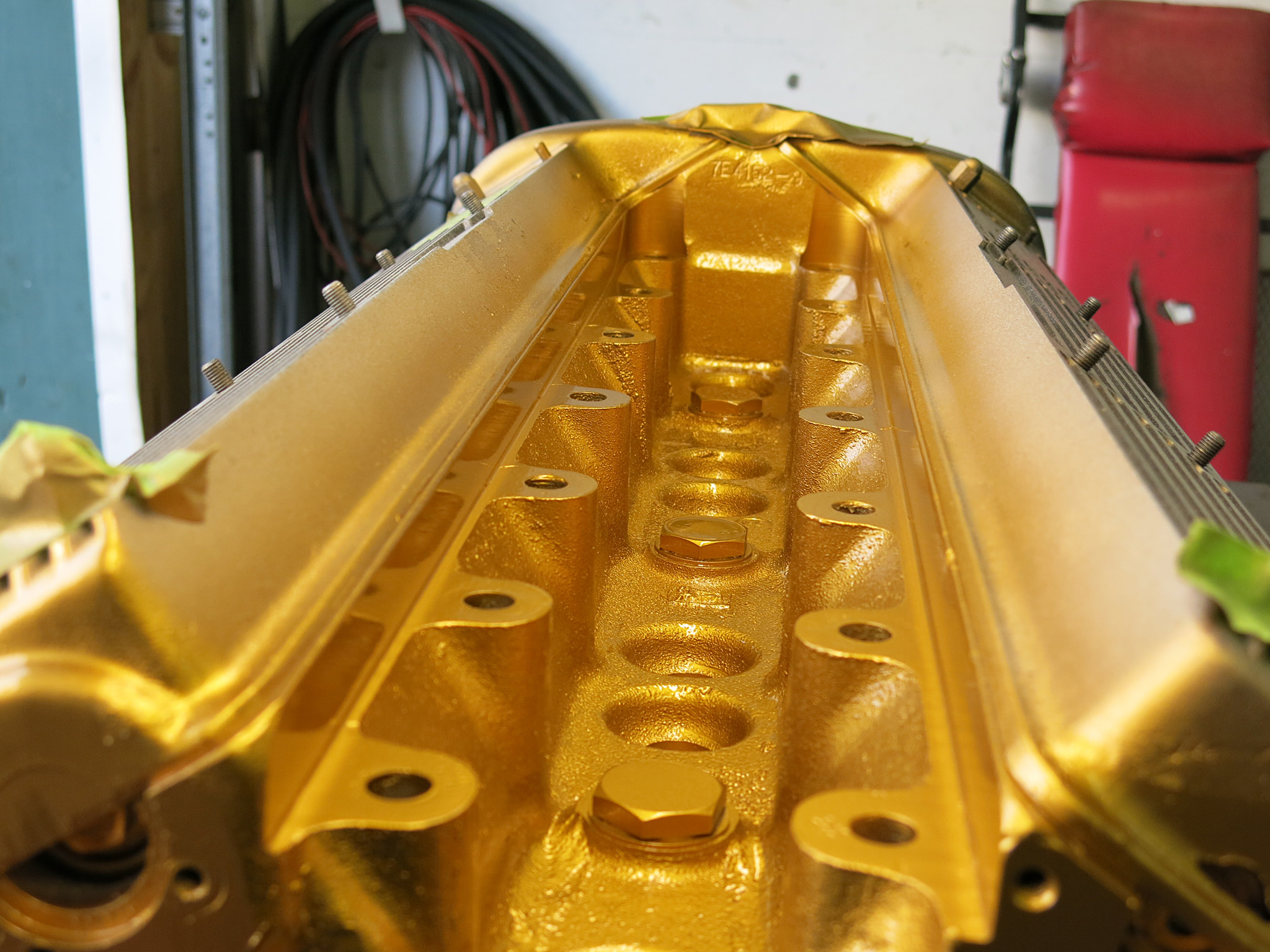

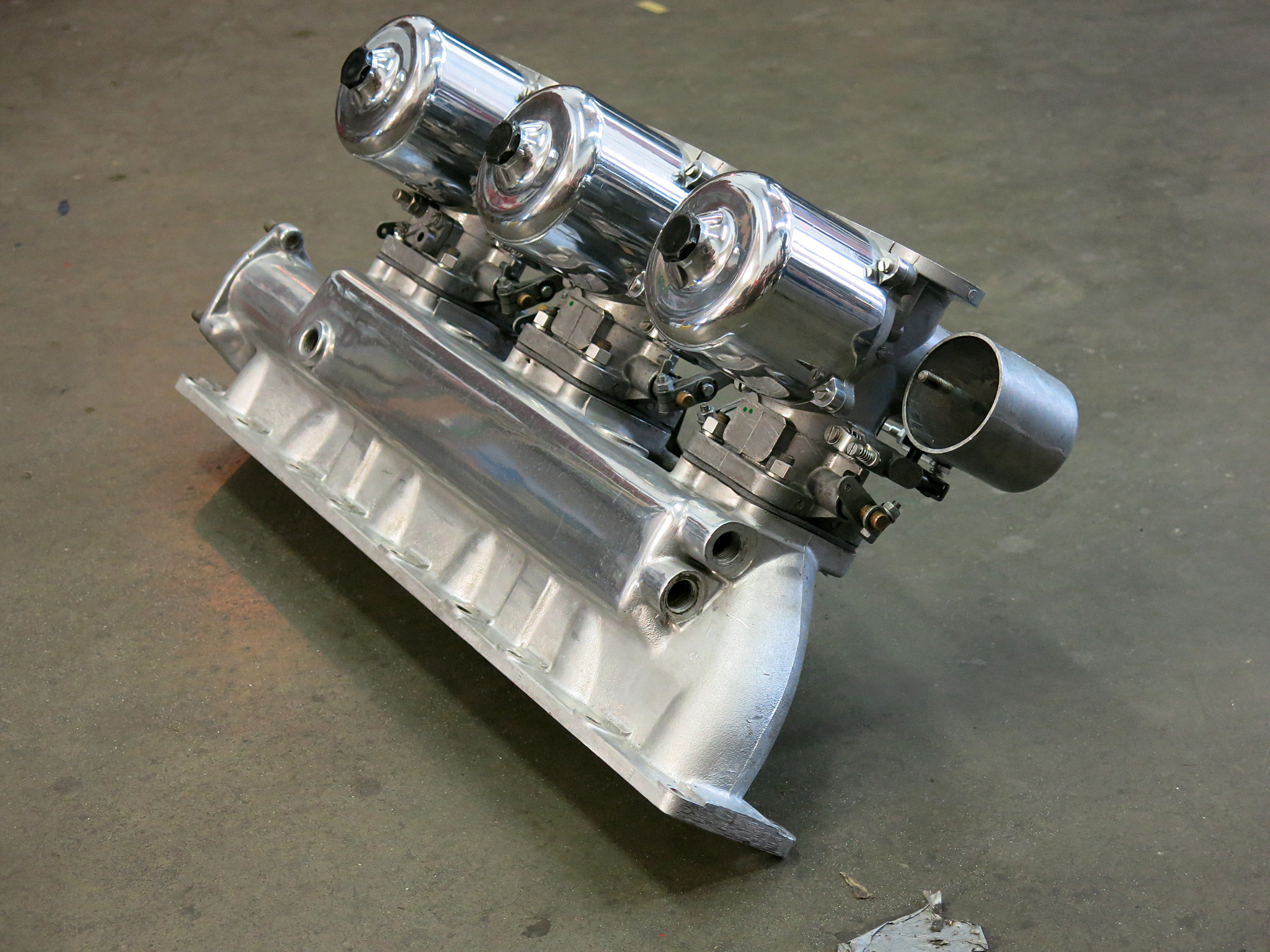

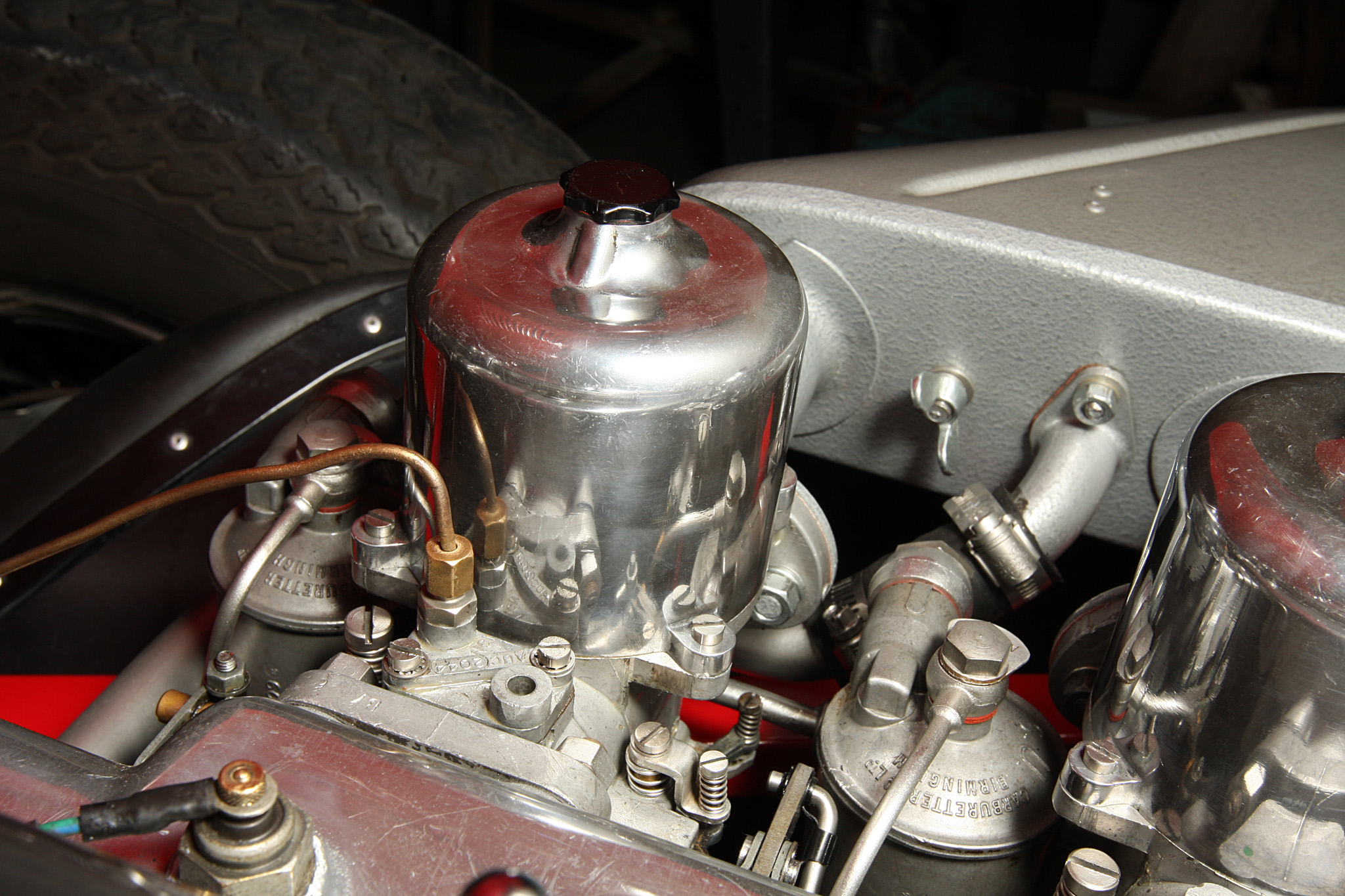

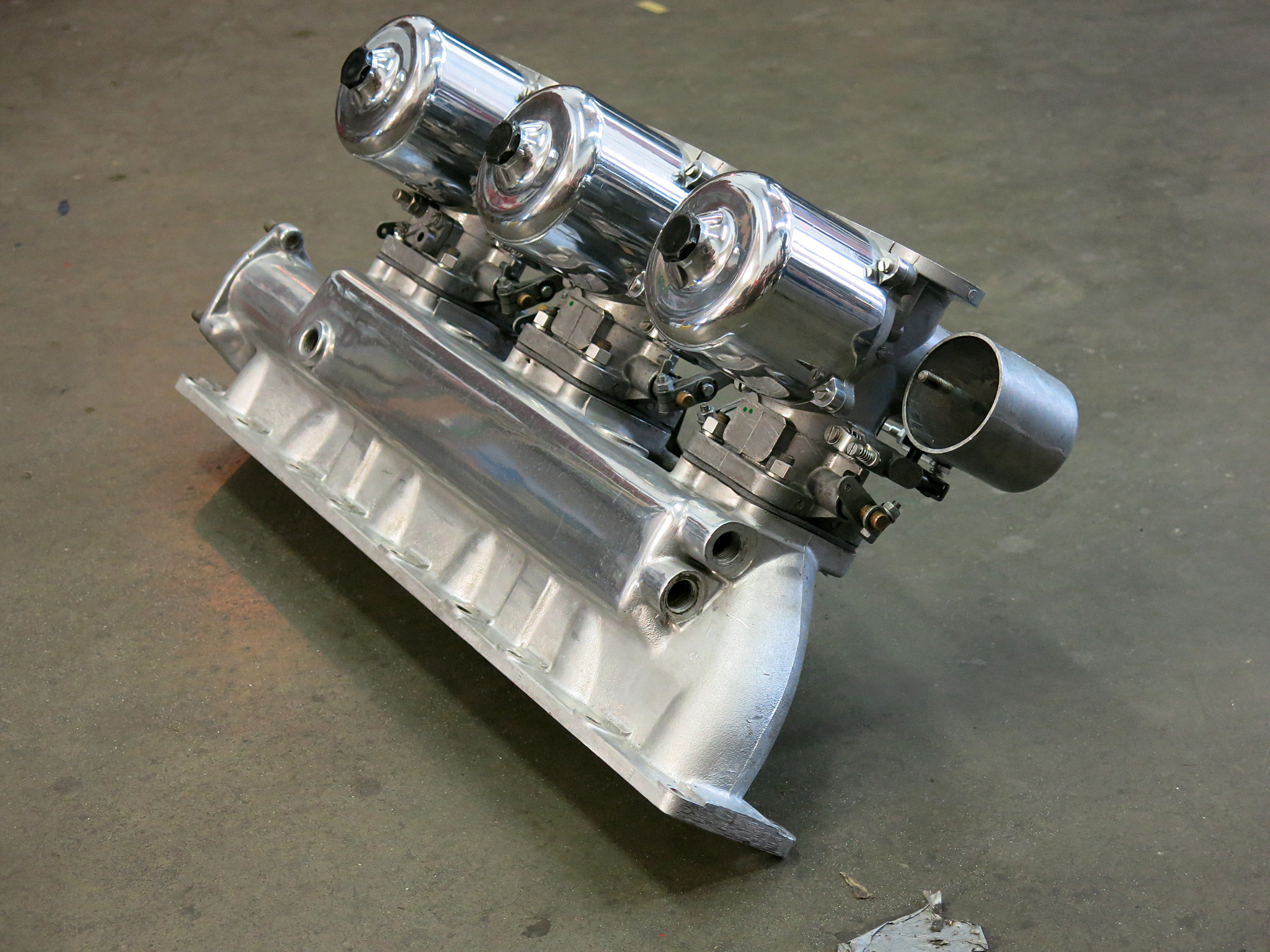

Tarting up the biggest piece of automotive jewelery is a time consuming task of cleaning and polishing. Specifically polishing the aluminum cam covers, cylinder head, intake manifold, breather tube and carburetor bodies whose radiant charm is offset by the bell housing, crankcase and transmission which stay in the bare and carefully cleaned aluminum alloy.

Last we have the intake and exhuast portion of this equation which include the porcelain covered exhaust manifolds. More on those later.

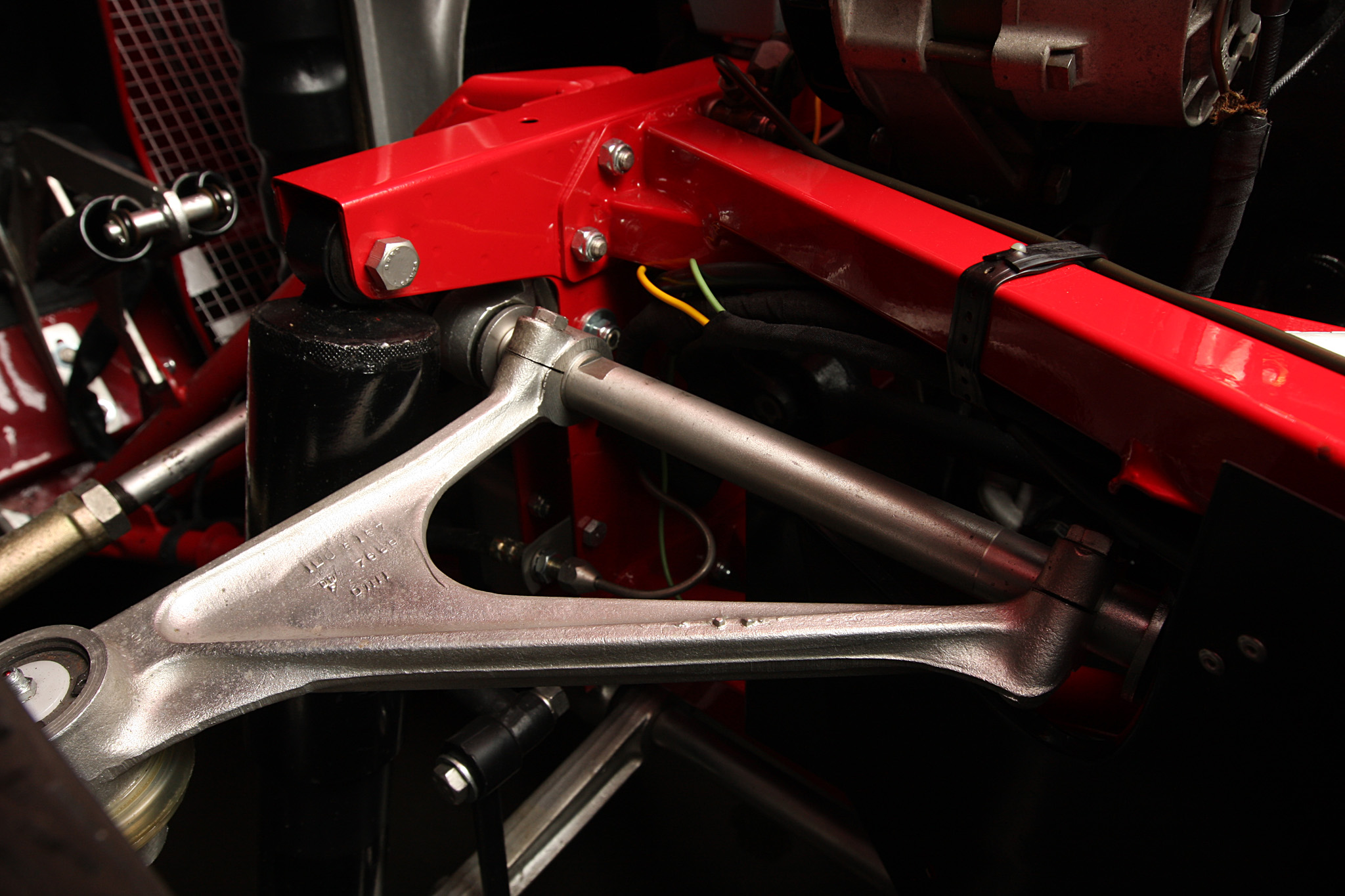

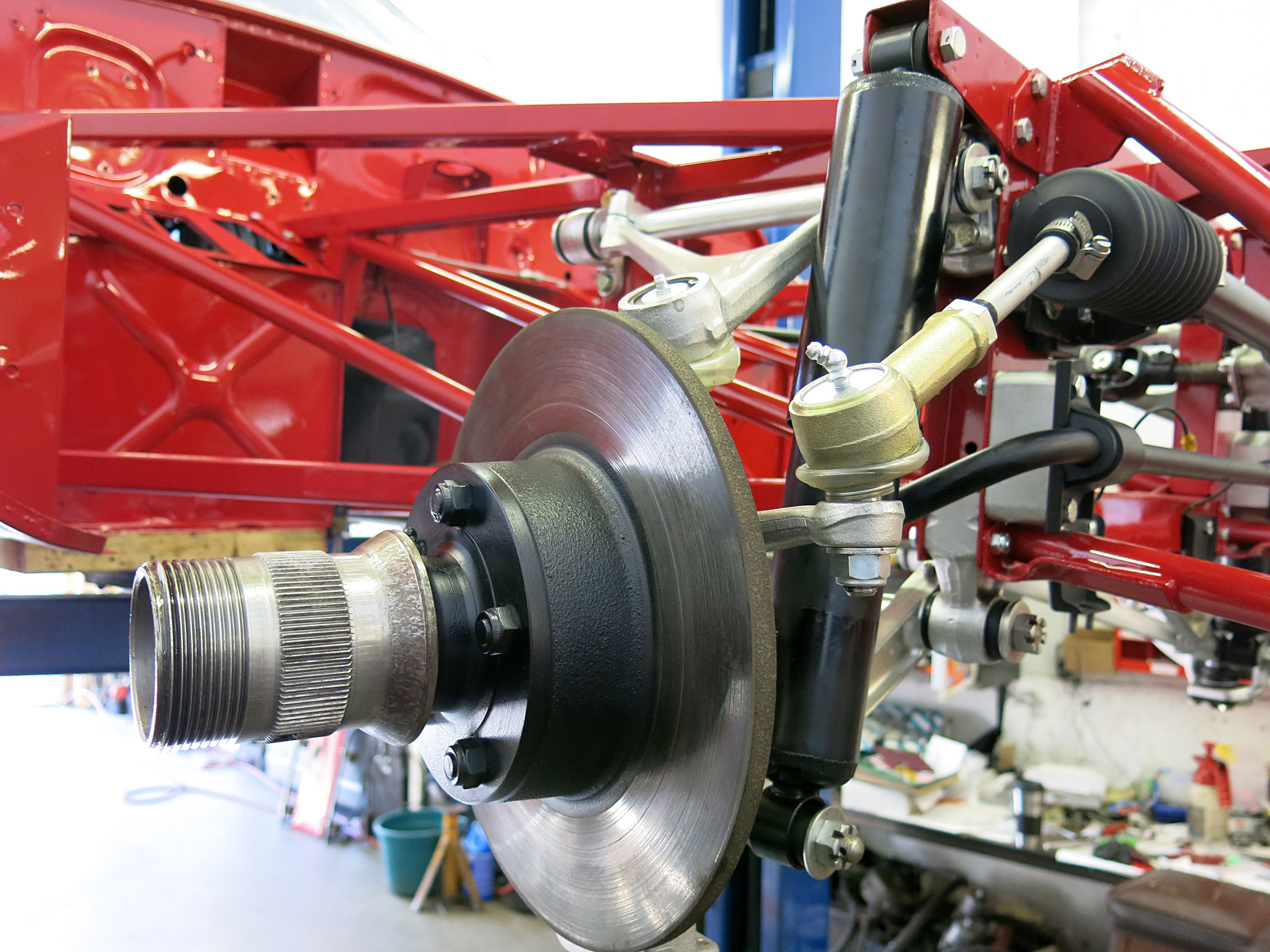

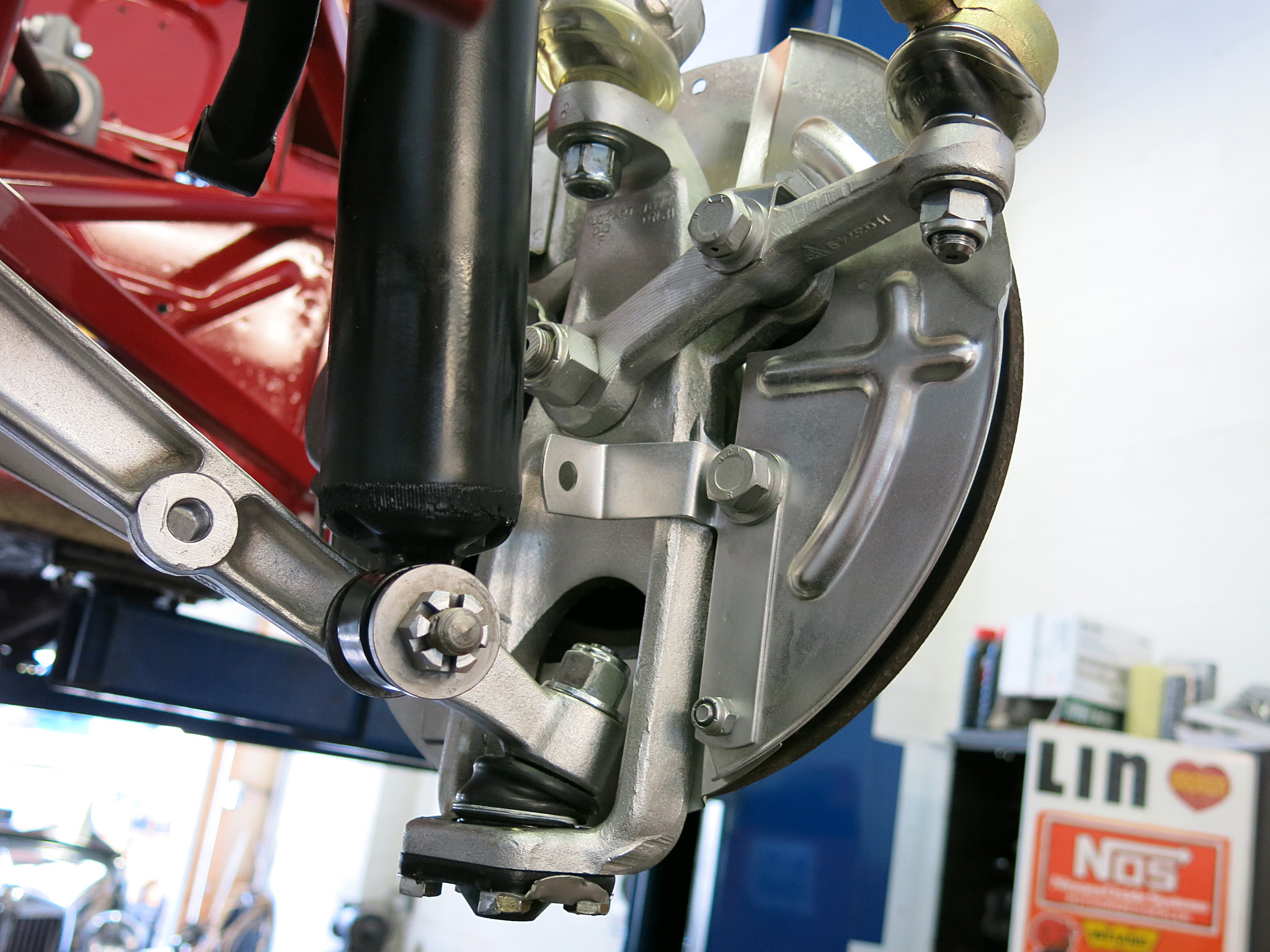

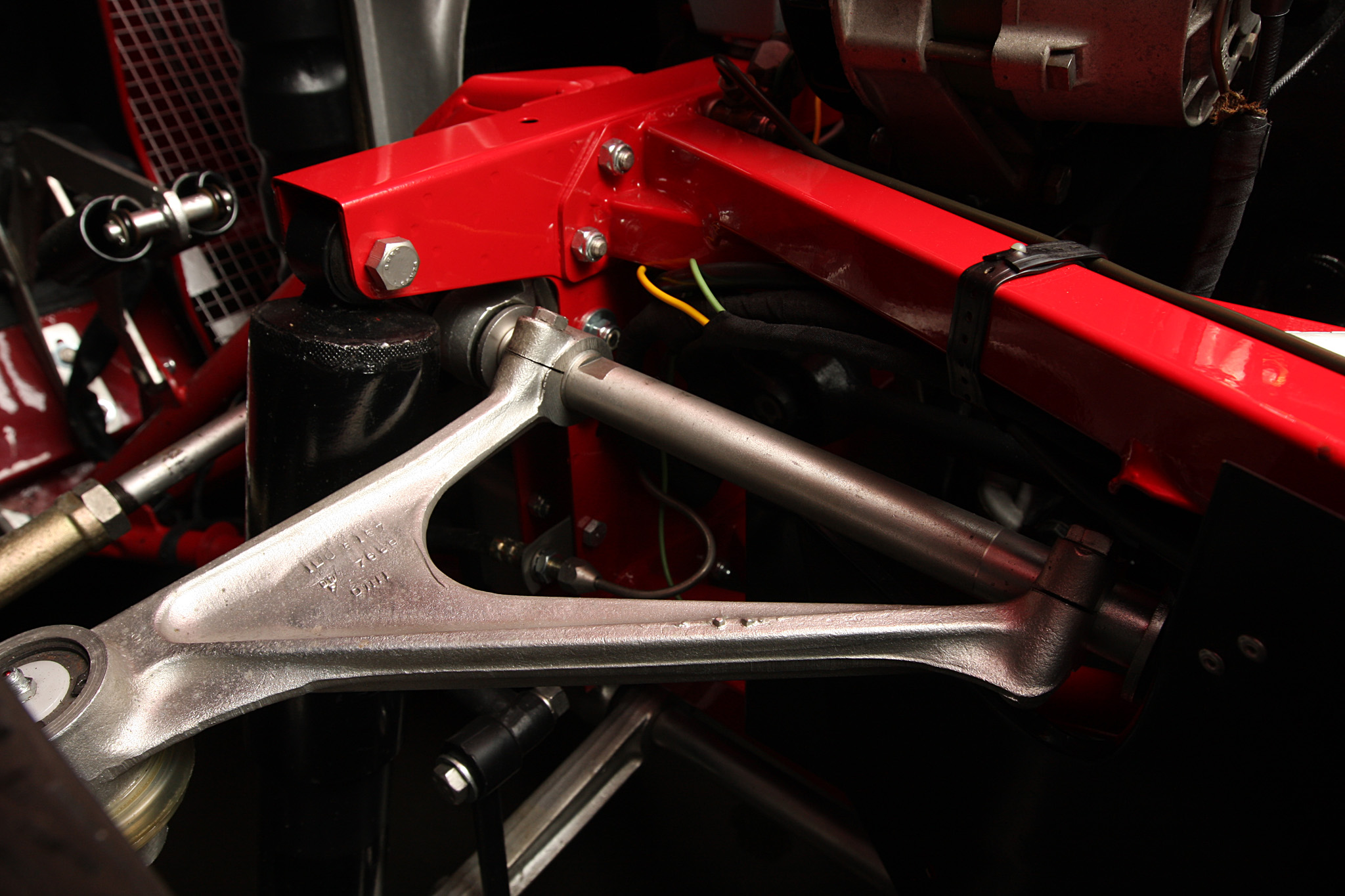

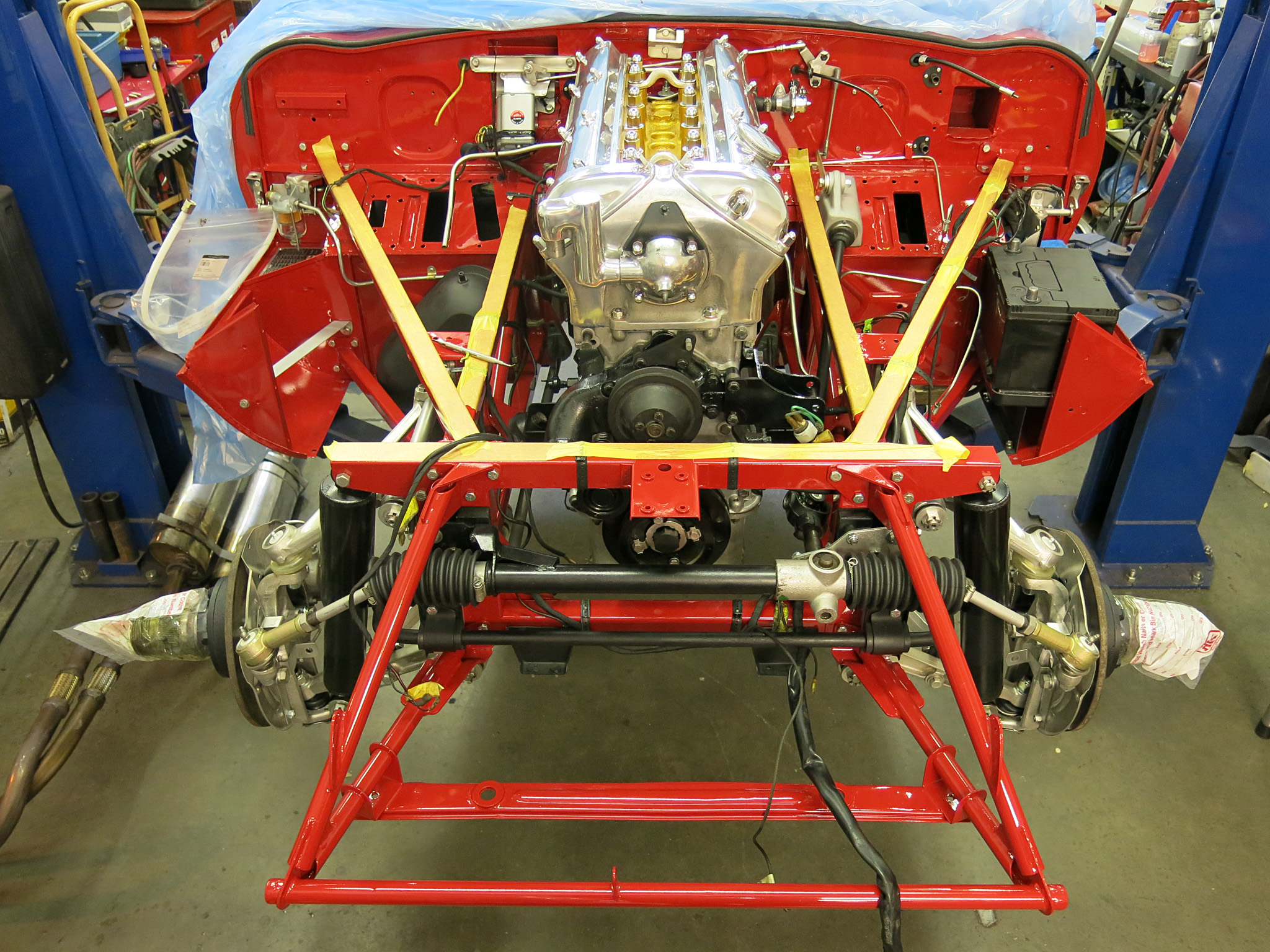

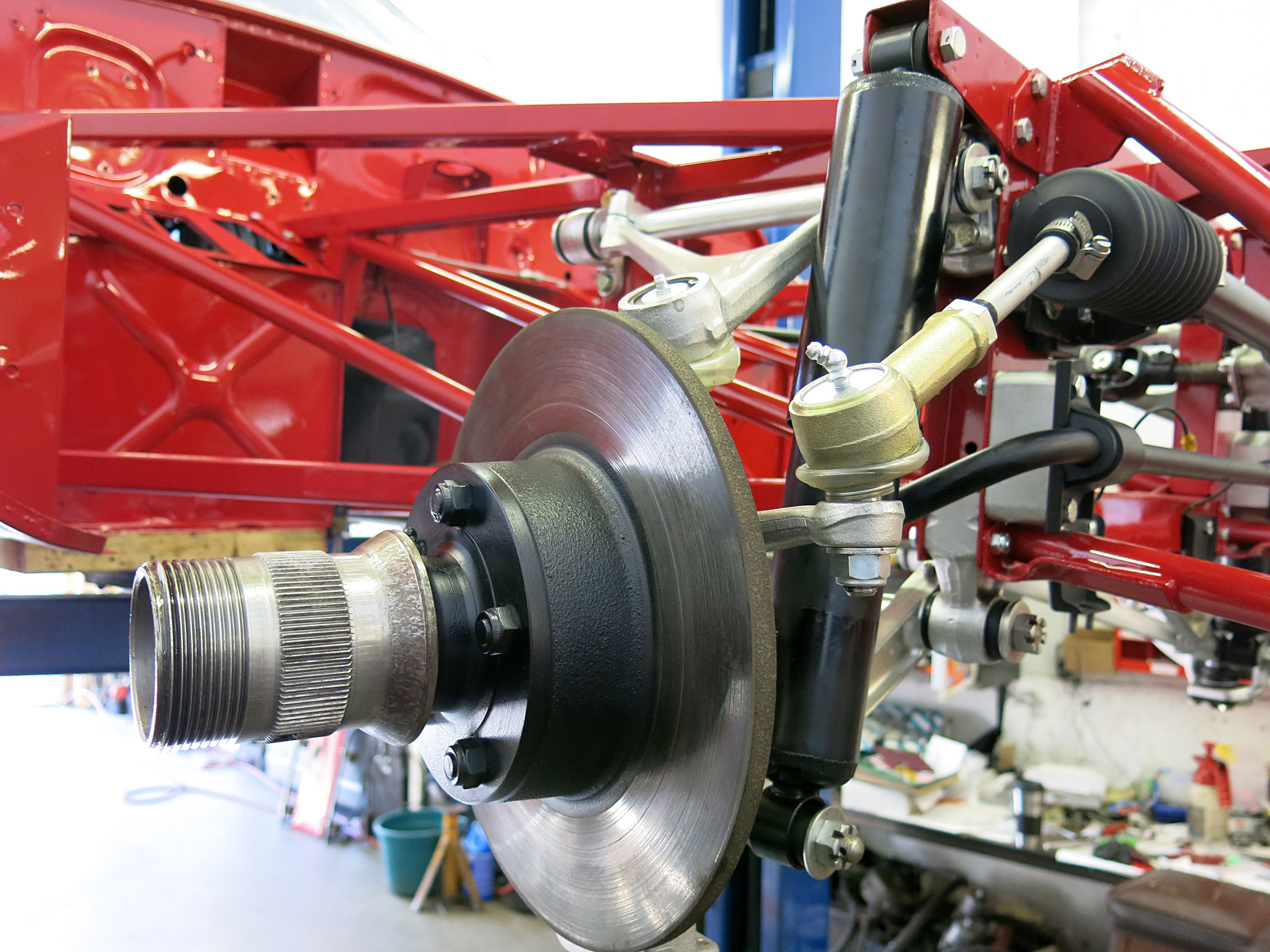

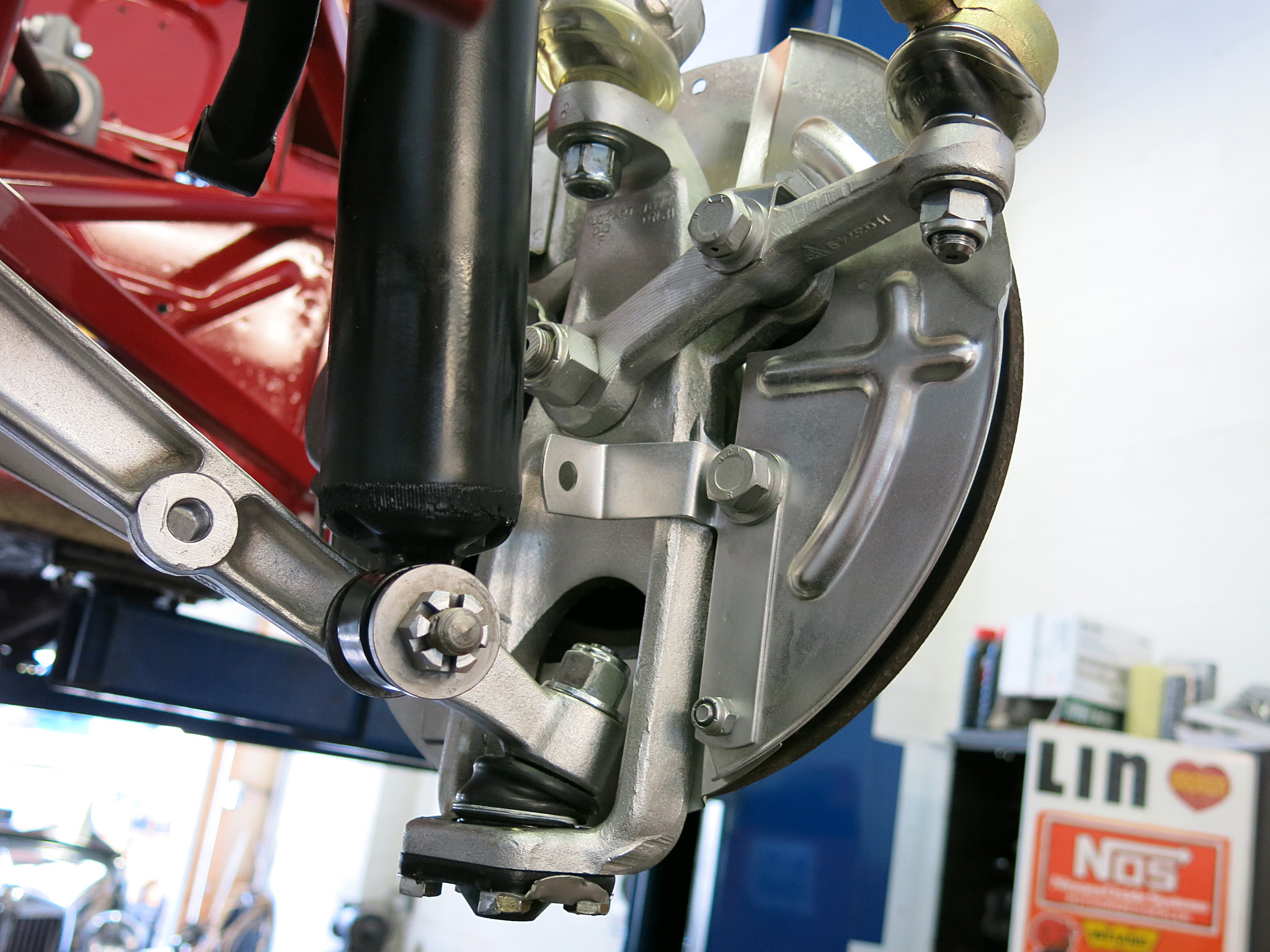

With the suspension now completely assembled, The Italian Job, our 1965 E-Type restoration, is coming along nicely and ready for phase two.

This week it was delivered back to our customer who will carry out some work and look after the car while we are away in Monterey.

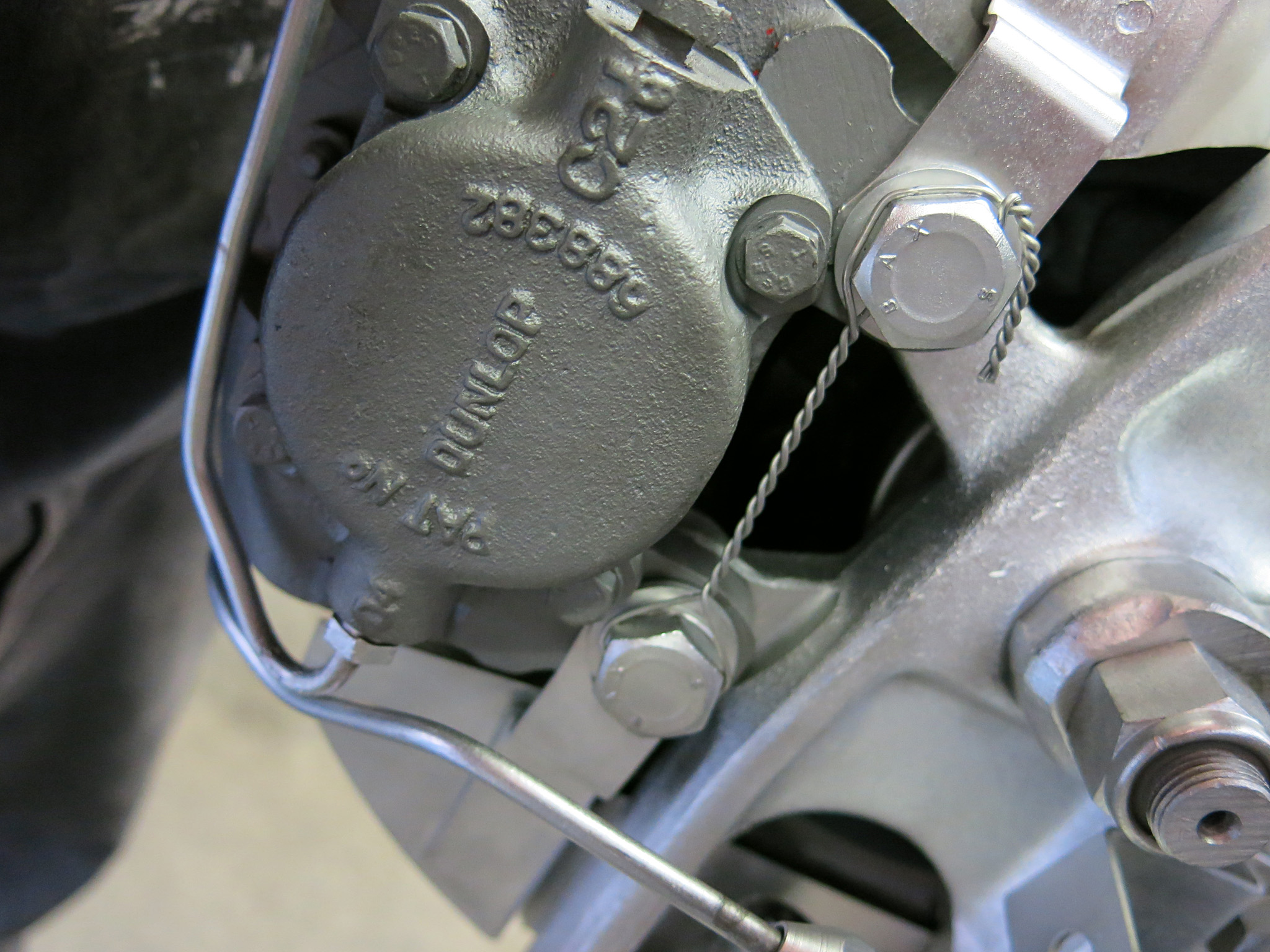

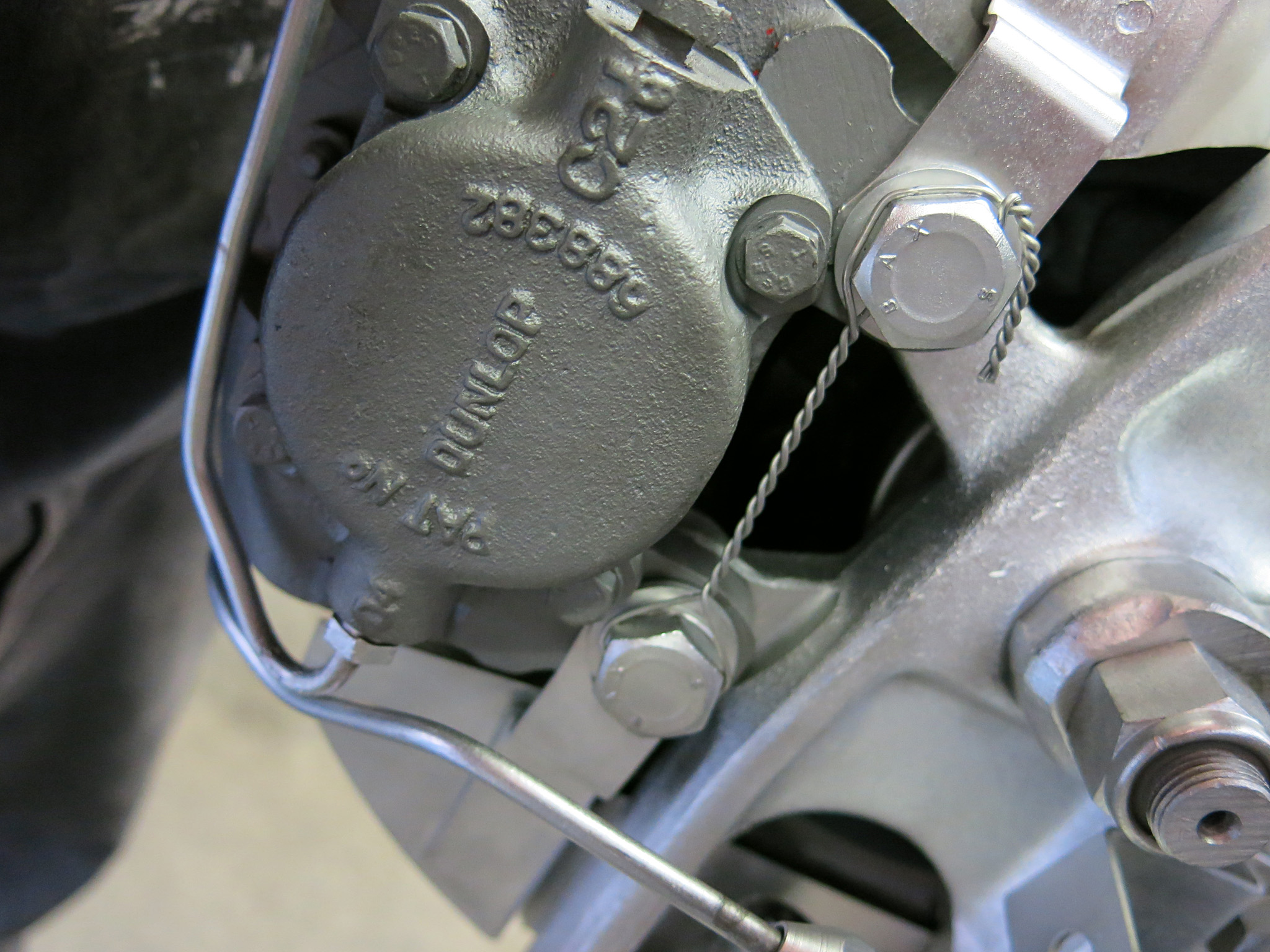

The entire assemblage benefits from CAD plating and a high regard for finished fit.

LH Torsion bar is installed to its factory original position.

Hubs are on and the torsion bar energy is forcing the suspension towards earth.

Fully plated stub axle carrier with matching guards, bolts, nyloc nuts and locking nuts look absolutely fabulous.

Twist Pliers and Lock Wire complete the look.